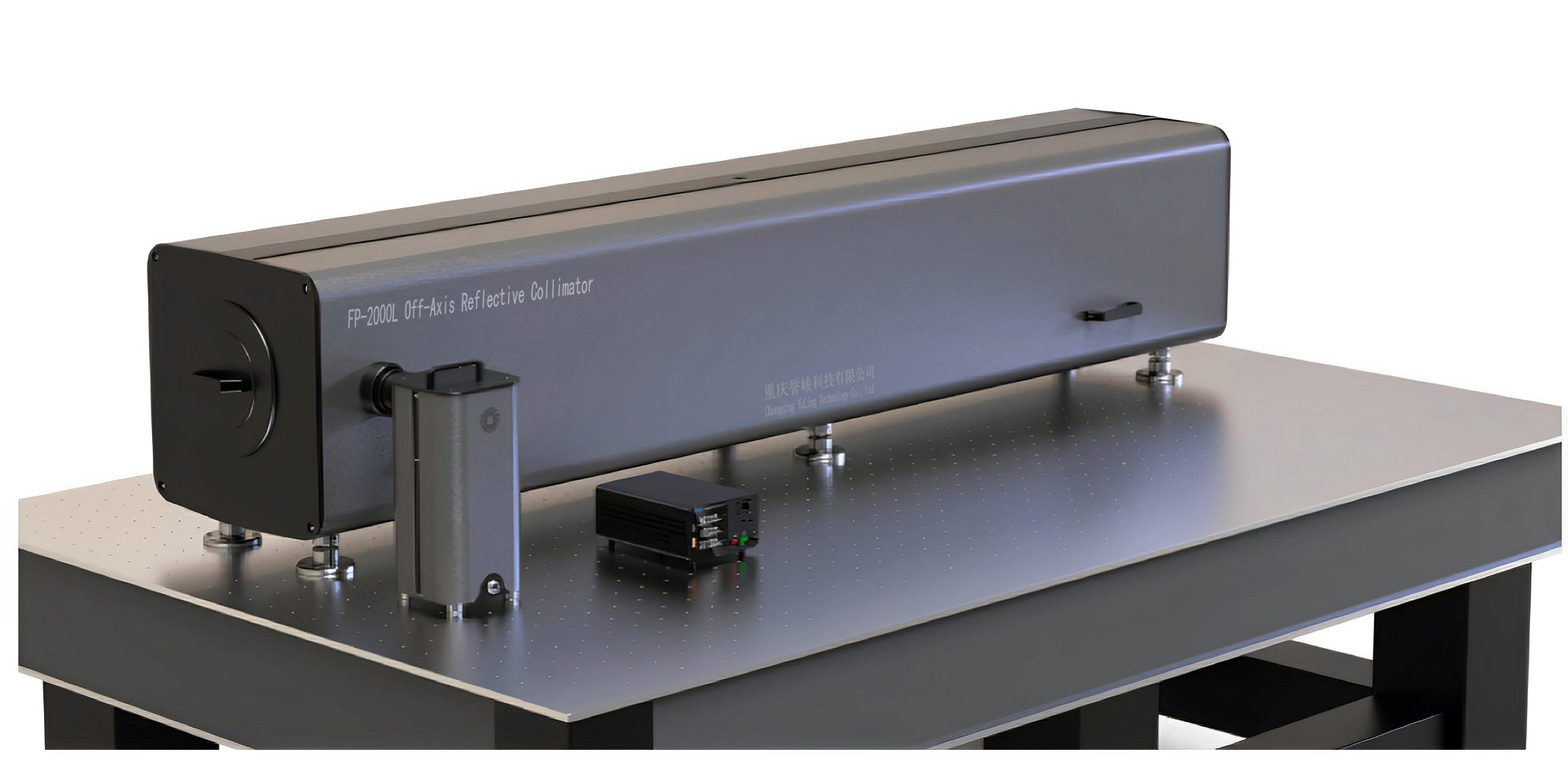

Off-Axis Reflective Optical Design

The FP-2000L Off-Axis Parabolic Collimator uses a 2000 mm focal length and Ø200 mm clear aperture to generate large, uniform parallel light. Its off-axis structure prevents central obstruction by separating the main and secondary mirrors, ensuring ≤5″ beam parallelism and RMS ≤ 1/40λ at 632.8 nm. The reflective system minimizes stray light, providing ultra-low divergence angles for optical axis alignment, image calibration, and infinite-target simulation across visible, infrared, and laser wavelengths.

Precision Reflective Optics And Lens Collimator Integration

The main mirror is made from quartz glass with aluminum + silicon protective coating, achieving ≥85% reflectivity and λ/20 wavefront accuracy over 80% of the aperture. Optional gold, silver, or dielectric coatings extend performance into infrared or laser applications. Acting as both reflective and lens collimator system, it supports field-of-view testing (≥0.8°) with exceptional image clarity and mechanical rigidity. Its design ensures stability against temperature drift, maintaining consistent optical alignment through long-term use.

Configurable Components And Testing Flexibility

This rectangular collimator system includes visible filters, attenuators, reticles, and a halogen light source. It supports various testing functions such as MRTD, MDTD, and SRF using four-bar, circular, and slit targets. Infrared reticles can be customized for blackbody source imaging, enabling accurate thermal calibration and image response verification. With interchangeable target plates and modular assemblies, the FP-2000L adapts easily to different test setups, improving versatility for optical metrology and aerospace-grade calibration.

Product Advantages

Ultra-High Parallelism And Beam Quality

Each Parabolic Collimator achieves ≤5″ parallelism through interferometric calibration. The off-axis reflective path ensures obstruction-free illumination, producing clean, stable beams essential for optical alignment and wavefront measurement applications.

Durable Coating And Optical Stability

With RMS ≤ 1/40λ surface precision and ≥85% mirror reflectivity, the reflective coating provides exceptional resistance to oxidation and spectral drift. This guarantees consistent optical fidelity across visible and infrared wavelengths, making the lens collimator suitable for both laboratory and industrial use.

Expert Engineering By A Leading Collimator Manufacture

As a trusted collimator manufacture, YuLing Technology integrates high-precision polishing, alignment, and quality control in every unit. Each system undergoes complete optical testing to verify accuracy and thermal reliability, ensuring reliable long-term performance in demanding optical and metrological environments.

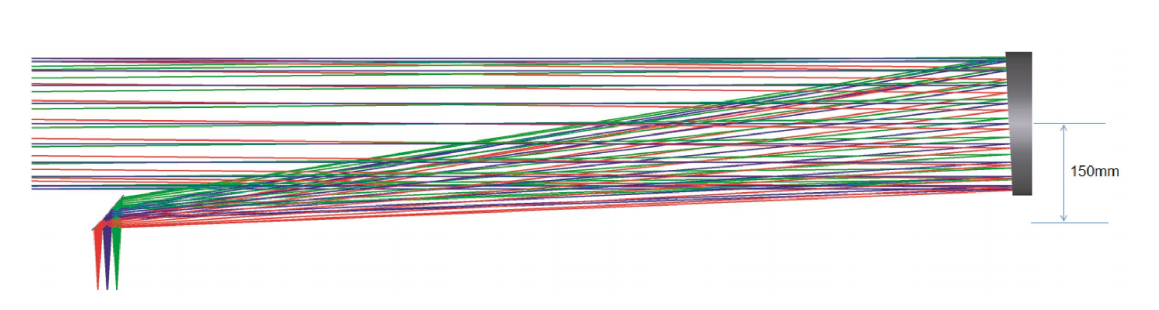

Optical path diagram:

- The main reflector adopts an off-axis surface mirror, select the appropriate off-axis, so that the reflected optical path deviates from the optical axis, avoids the secondary reflector from interfering with the light-passing optical path, and ensure that the φ200mm light-permeable area is unobstructed.

- The secondary mirror adopts a plane reflector, which undertakes the reflected light path of the main reflector and turns the light path, so that the reflected light path is located on the side of the light outlet, which is convenient for later debugging and use.

- The focal plane position is the target surface installation position. Each target plate is installed in the dividing plate frame separately. Through later debugging, each target plate is placed in the focal surface position after separate assembly to realize the target plate replacement function.

Standard Components:

- Collimator Main Unit: 1 set

- Filters: 2 pieces (Orange, center wavelength 600nm; Green, center wavelength 532nm)

- Attenuator: 1 piece (Neutral Attenuator 430–730nm)

- Visible Reticles: 12 pieces(Crosshair Reticles*1,Resolution Reticles*5:1#/2#/3#/4#/5#,Star Point Reticles*5: 0.1/0.2/0.01/0.02/0.05,Porro Board*1)

- USAF 1951 Resolution Reticle: 1 piece

- Light Source Assembly: 1 set( 12V30W Halogen Light Source)

Custom Components (Applicable to Infrared Reticles):

Infrared targets are formed by machining various patterns into thin metal plates. When illuminated by a blackbody source, the thermal imager under test observes sharp target patterns against a uniform background. A variety of standard infrared targets are available for customization.

Examples of Targets:

- Four-Bar Target: For Minimum Resolvable Temperature Difference (MRTD) testing.

- Circular Target: For Minimum Detectable Temperature Difference (MDTD) testing.

- Slit Target: For Slit Response Function (SRF) testing.

- Cross-Circle Target: For axis alignment, aiming, and focusing.

- Distortion Target: For testing camera distortion in image generation.

- Outline Target: For evaluating target recognition range of the camera under test.

- Square Target: For testing Noise Equivalent Temperature Difference (NETD), Fixed Pattern Noise (FPN), Signal Transfer Function (SITF), and Aperiodic Transfer Function (ATF).

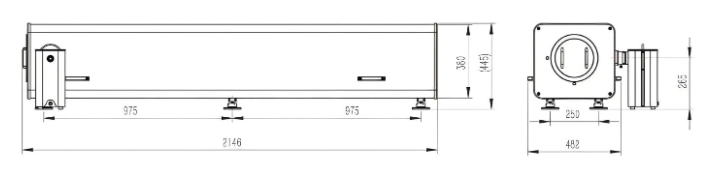

External dimensions:(Unit: mm)

About Us

YuLing Technology, headquartered in Chongqing, China, is a professional optical instrument manufacturer focused on designing and producing high-precision metrology systems. Its core product lines include collimators, autocollimators, optical benches, and photoelectric measuring instruments. With an R&D center in Xi’an, YuLing serves aerospace, defense, and industrial applications requiring superior optical precision. The company combines advanced optical design, mechanical processing, and electronic control technologies to provide comprehensive, customizable solutions that meet international standards of performance and reliability.

Contact YuLing for expert consultation and custom optical calibration solutions today!

FAQ – Frequently Asked Questions

What precision can the FP-2000L Parabolic Collimator achieve?

It delivers ≤5″ beam parallelism and RMS ≤1/40λ surface accuracy for high-stability optical calibration.

Can the reflective coating be customized for different wavelengths?

Yes, aluminum + Si is standard, with optional gold, silver, or dielectric coatings for extended spectral response.

Does the rectangular collimator support both visible and infrared testing?

Yes, it supports visible, infrared, and laser wavelengths, compatible with MRTD and SRF testing modules.

What components are included with the system?

It includes a halogen light source, visible filters, neutral attenuators, and multiple precision reticle plates.

How long is the production or customization cycle?

Standard delivery takes 4–6 weeks, depending on configuration and additional infrared target requirements.