Applications:

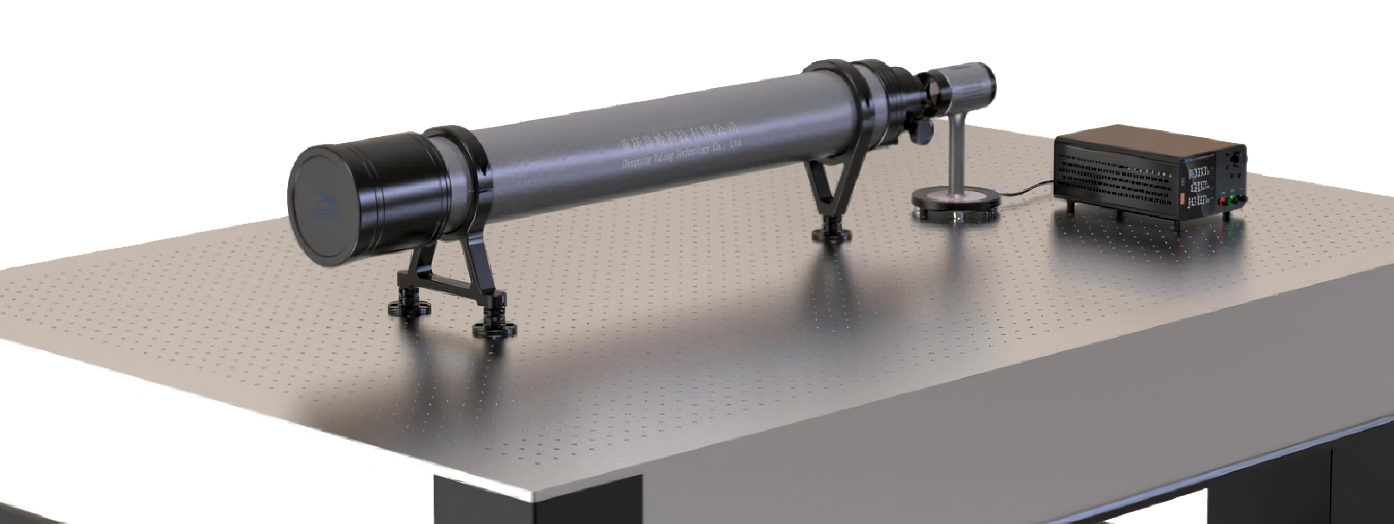

The F-1000 Collimator Tube is an instrument used to generate a large-diameter parallel light beam, with a wide range of applications. By selecting different reticle plates and pairing it with various accessories such as observation microscopes, front mirrors, it can be used for the following purposes:

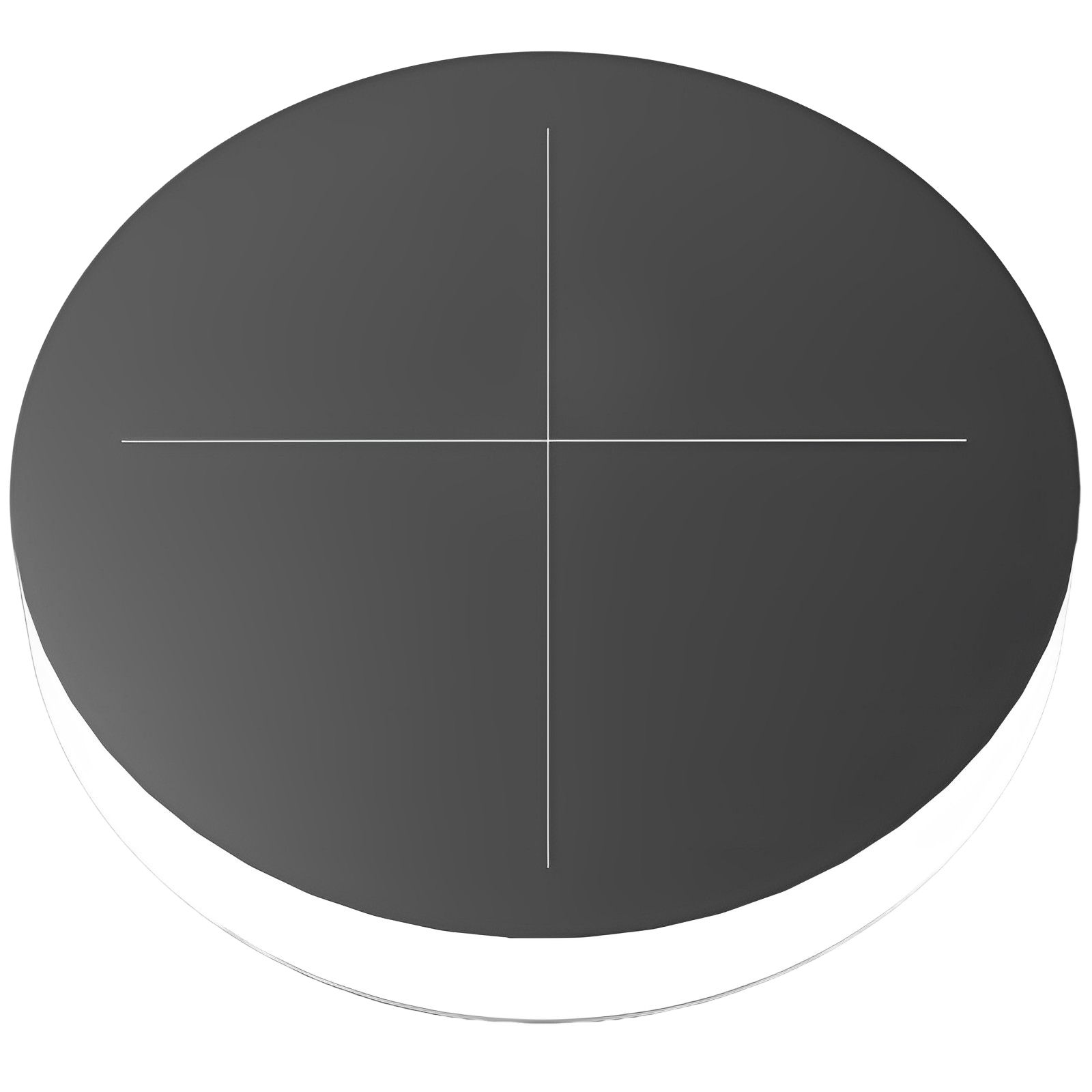

1. As a fundamental tool for optical instrument alignment and adjustment.

2. With the selection of a Borosilicate plate and paired with a reading microscope or measuring microscope, it can be used for measuring the intercepts and focal lengths of lenses and various objective lenses.

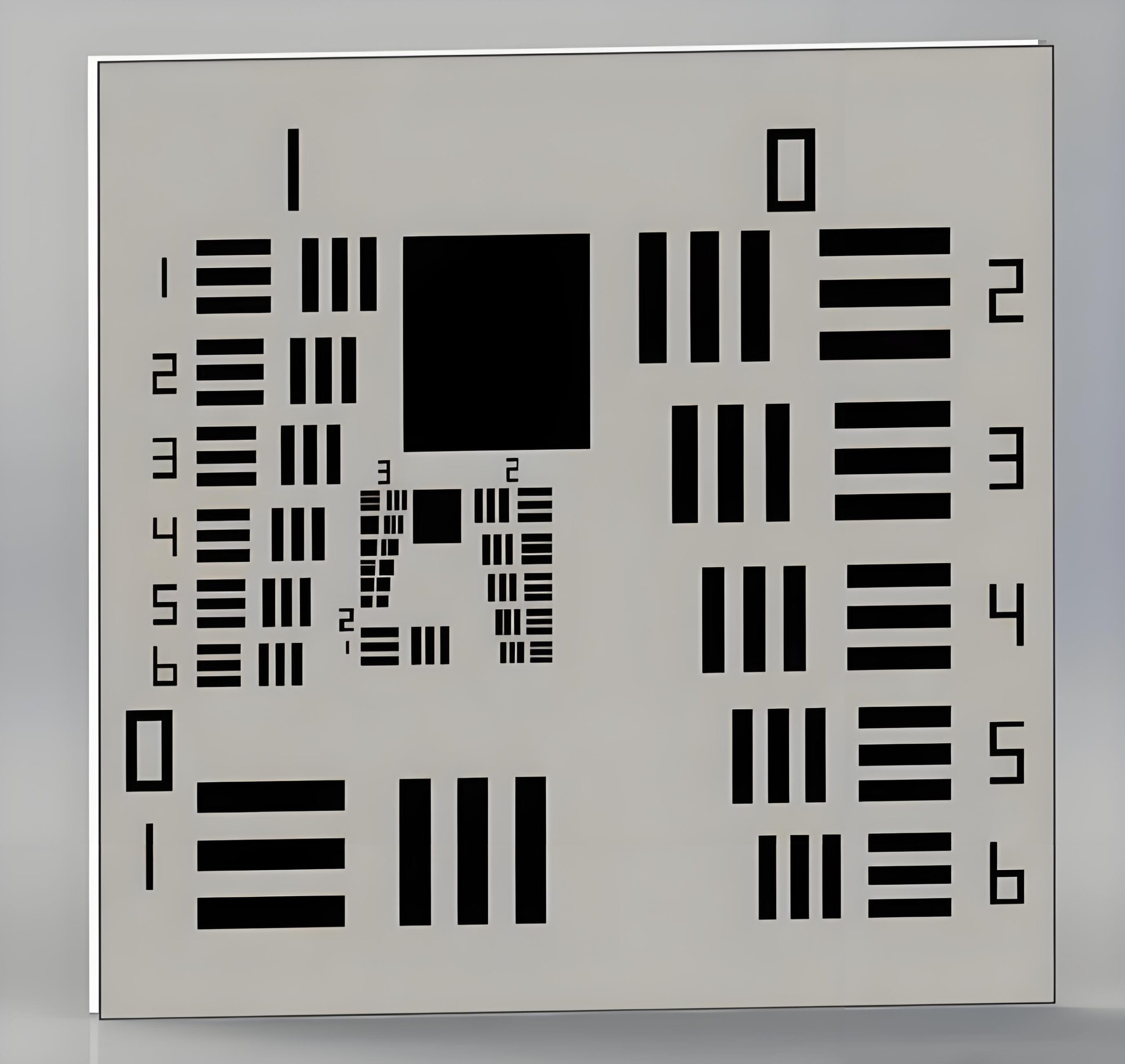

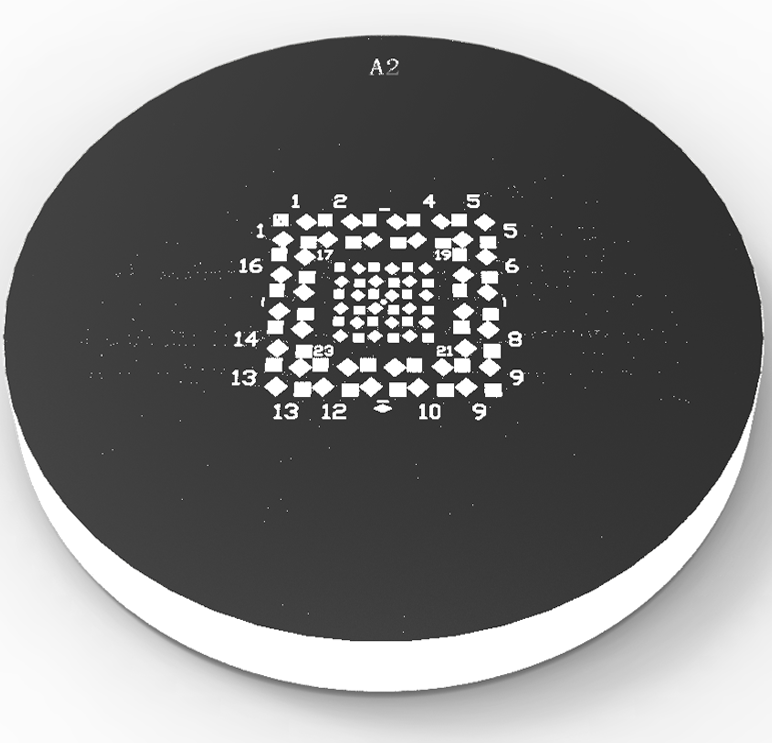

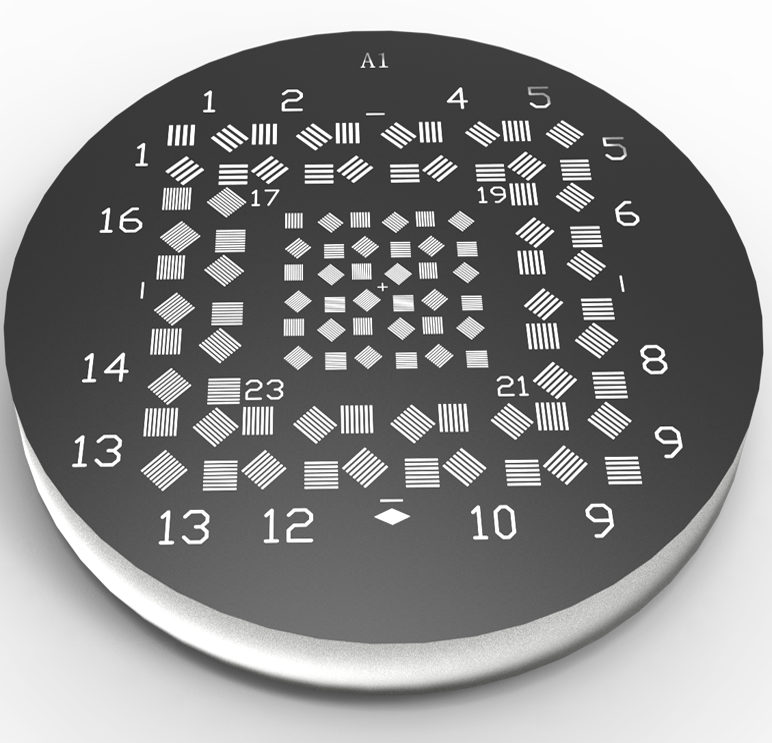

3. With the selection of an appropriate resolution plate, and paired with an observation microscope and front mirror, it can be used for determining the resolution of lenses, prisms, plane mirrors, and various objective lenses, as well as for assessing image quality by observing resolution patterns.

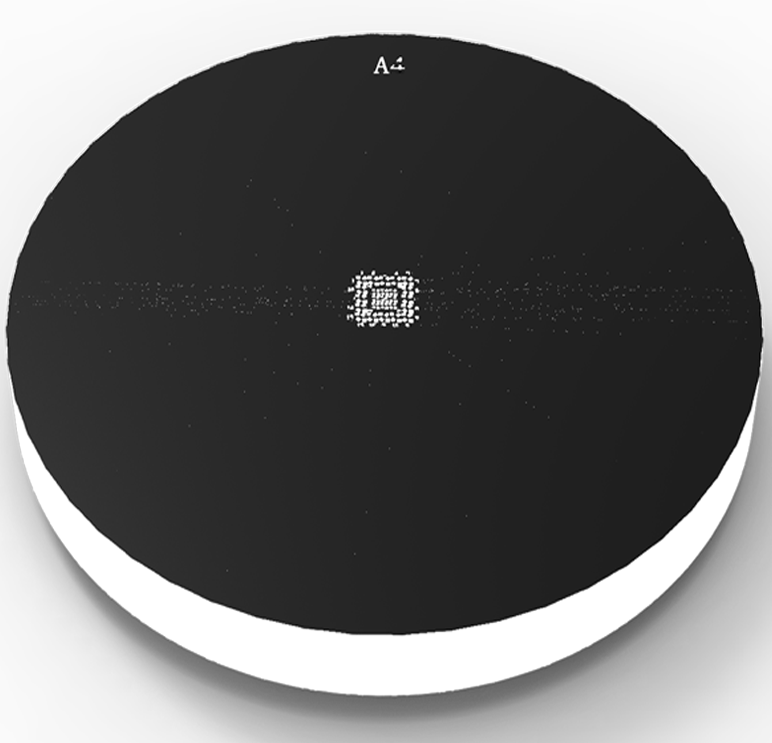

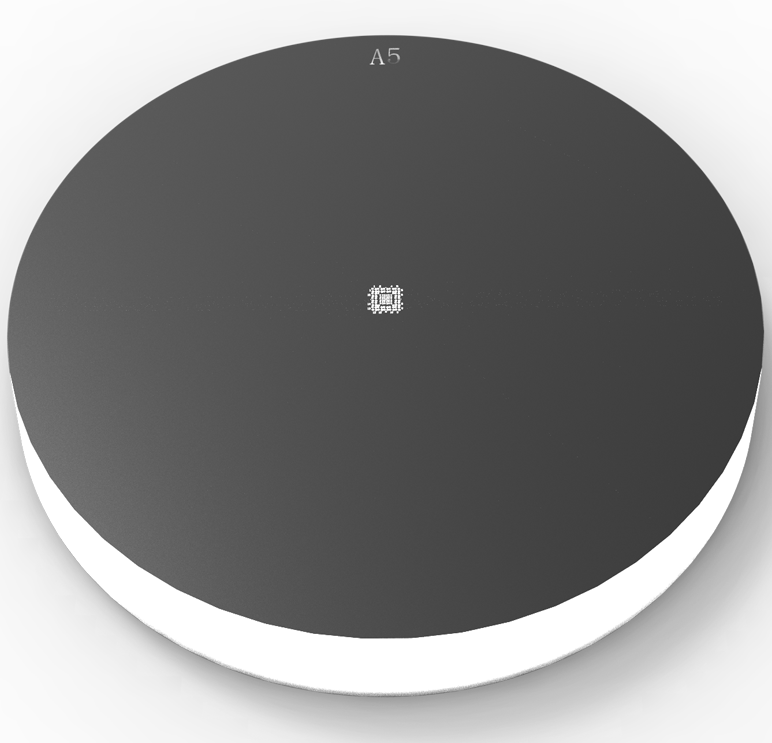

4. With the selection of an appropriate star pattern plate and paired with an observation microscope and front mirror, it can be used to evaluate the image quality of lenses, prisms, plane mirrors, and various objective lenses.

5. By equipping the instrument with specialized mirrors and measuring eyepieces, it can be used to measure straightness or flatness deviations of rails and large flat surfaces.

6. As a tool for aiming at long-distance targets. Additionally, the F Series Collimator Tubes are essential test reference components for optical material uniformity checks and the calibration of various optical mounts. Therefore, they are commonly used in the production, research, and teaching of optical instruments.

High-Precision Optical Alignment Structure

The YuLing collimator adopts a refined optical design that ensures parallel beam output and structural stability during operation. Its precision mechanical assembly maintains alignment accuracy between the optical axis and mechanical center, achieving repeatable calibration results. The focus adjustment mechanism allows fine tuning without affecting beam quality, supporting precise optical alignment in laboratories and metrology applications.

Advanced Collimator Lens Engineering

At the heart of the system is a multi-element collimator lens with optimized curvature and anti-reflection coating. This configuration minimizes aberrations and enhances transmission efficiency. Each optical component is produced under strict tolerance control to ensure reliable wavefront accuracy. The housing uses aerospace-grade aluminum alloy, providing excellent thermal stability and resistance to deformation for consistent optical performance under varying environmental conditions.

Flexible Integration And Functional Versatility

YuLing’s modular pinhole collimator fits seamlessly into optical benches and photometric systems. It can be configured for use with cameras, sensors, or laser-based instruments. The collimation source delivers stable illumination and repeatable geometry, supporting optical calibration in aerospace testing, industrial quality control, and academic research. Its adaptable mounting interface ensures easy integration into both new and existing optical setups.

Product Advantages

Exceptional Beam Stability And Accuracy

The optical assembly maintains beam coaxial precision even during long operation. The collimator design compensates for vibration and thermal expansion, preserving angular consistency and optical stability. This guarantees dependable measurement repeatability for alignment verification, focus calibration, and sighting equipment testing.

Superior Light Transmission And Optical Clarity

Each collimator lens is processed with multilayer coatings to achieve high transmission and reduced stray reflection. The result is a clean, uniform beam ideal for imaging calibration and high-resolution optical inspection. The optical path design minimizes distortion and chromatic aberration, providing consistent measurement accuracy across a wide field.

Professional Collimator Manufacture And Customization

As an experienced collimator manufacture, YuLing Technology provides tailored optical solutions based on client specifications. The company’s integrated production system covers precision machining, coating, and optical assembly. Each unit undergoes inspection for beam divergence, focal length accuracy, and alignment precision. This rigorous process ensures durable performance and reduced recalibration requirements over time.

Working Principle:

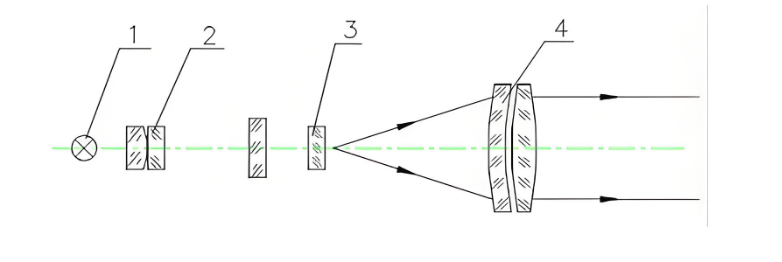

As shown in the figure below, the reticle serving as the target is uniformly illuminated by light source 1 through various color filters 2. If the reticle 3 is correctly positioned at the focal plane of the objective lens 4, the light emitted from the objective lens forms a parallel light beam, which is equivalent to light originating from infinity.

Optical path diagram:

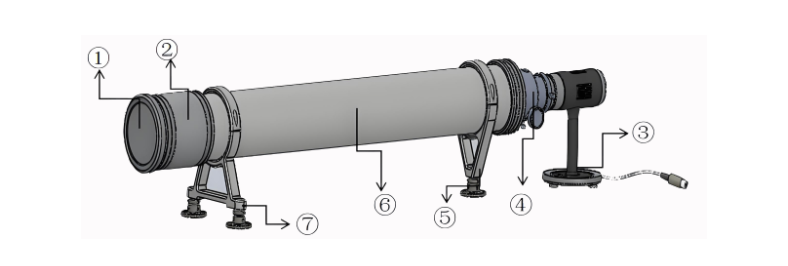

Product structure:

① Lens Cap ② Objective Lens Assembly ③ Light Source ④ Focusing Base ⑤ Rear Support Assembly ⑥ Collimating Tube ⑦ Front Support Assembly

Standard Components:

Collimator Main Unit: 1 piece(Equipped with a fine-tuning foot bracket)

Filters: 2 pieces (Orange, center wavelength 600nm; Green, center wavelength 532nm)

Attenuator: 1 piece (Neutral Attenuator 430–730nm)

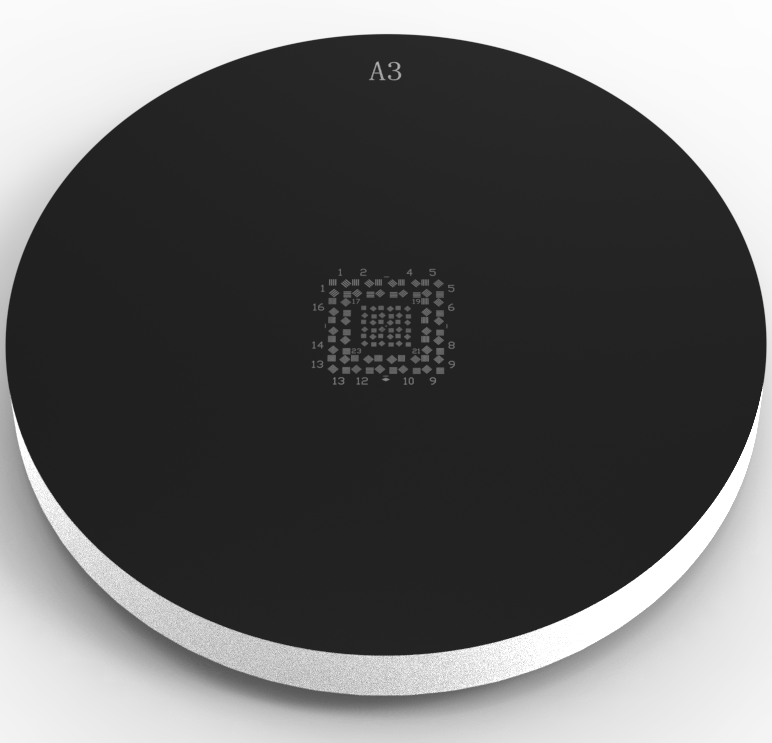

Visible Reticles: 11 piece(Crosshair Reticles*1,Resolution Reticles*4 :1#2#/3#/4#,Star Point Reticles*5: 0.1/.01/0.2/0.02/0.05,Porro Board*1)

DC voltage stabilizing power supply: 1 piece (Output voltage:0-30V,Output current:0-5A)

Light Source Assembly: 1 set (12V20W halogen light source)

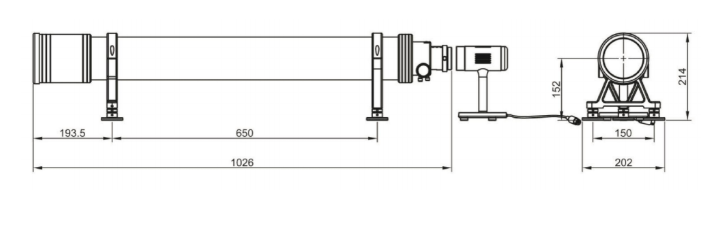

External dimensions:(Unit: mm)

About Us

YuLing Technology, headquartered in Chongqing, China, specializes in developing and manufacturing high-precision optical and photoelectric measurement instruments. With a dedicated R&D center in Xi’an, the company focuses on the design and production of collimators, autocollimators, optical benches, and custom calibration systems. YuLing’s expertise spans optical engineering, precision mechanics, and digital control integration, enabling delivery of reliable tools for aerospace, defense, marine, and industrial metrology sectors. Upholding the principles of quality and integrity, YuLing provides dependable, high-accuracy instruments backed by comprehensive technical support and long-term service partnerships. Request technical consultation or customized calibration solutions from YuLing today!

FAQ – Frequently Asked Questions

How is optical accuracy ensured in each collimator?

Every instrument undergoes metrological testing on certified optical benches to verify beam parallelism, focal precision, and repeatability.

Can the collimator lens be cleaned or replaced?

Yes. YuLing provides maintenance and replacement services performed by trained optical engineers to maintain original specifications.

Does the pinhole collimator support third-party integration?

It follows standard optical interface dimensions, making it compatible with various optical instruments and measuring platforms.

What is the estimated delivery time for customized models?

The production cycle ranges from four to six weeks, depending on the required optical configuration and quantity.

Is there technical support after delivery?

YuLing offers one-year warranty coverage and long-term technical assistance for recalibration and performance verification.