When satellite remote sensing cameras need to accurately capture surface textures hundreds of kilometers away; when UAV optoelectronic pods must lock onto millimeter-level defects at an altitude of 100 meters; when lithography machine lenses require nanometer-level precision imaging— the “visual calibration” of these high-precision optical devices relies on a core component: the off-axis collimator.

The core value of off-axis collimators lies in establishing “traceable optical standards.” Its principle, though seemingly simple, is highly sophisticated: through a built-in high-precision target reticle and high-quality optical lens group, it converts target images into parallel light beams, providing a standard reference of “infinite-distance targets” for tested optical equipment. Popularly speaking, it acts like a “standard ruler” in optical testing, exposing all “visual defects” of the tested equipment—whether lens distortion, insufficient resolution, or optical axis deviation—all can be accurately quantified by comparing with the standard images provided by the collimator.

However, manufacturing high-quality off-axis collimators is no easy task, as the industry faces multiple technical challenges: top international standards require collimation accuracy of ≤0.1μrad (microradian), equivalent to a positioning error of no more than 0.1 millimeters at 1 kilometer; under extreme temperatures of -40℃~+60℃, thermal deformation of lens groups and reticles may cause collimation accuracy drift exceeding 50%; moreover, differences in focal length and field of view of different tested equipment place extremely high demands on the adaptability of collimators. Insufficient accuracy of the collimator itself will directly lead to “calibrating errors with errors”—for example, a device with collimation accuracy of only 0.5μrad can never meet the 0.1μrad testing requirement of UAV pods, ultimately resulting in terminal equipment being put into use with “hidden defects.”

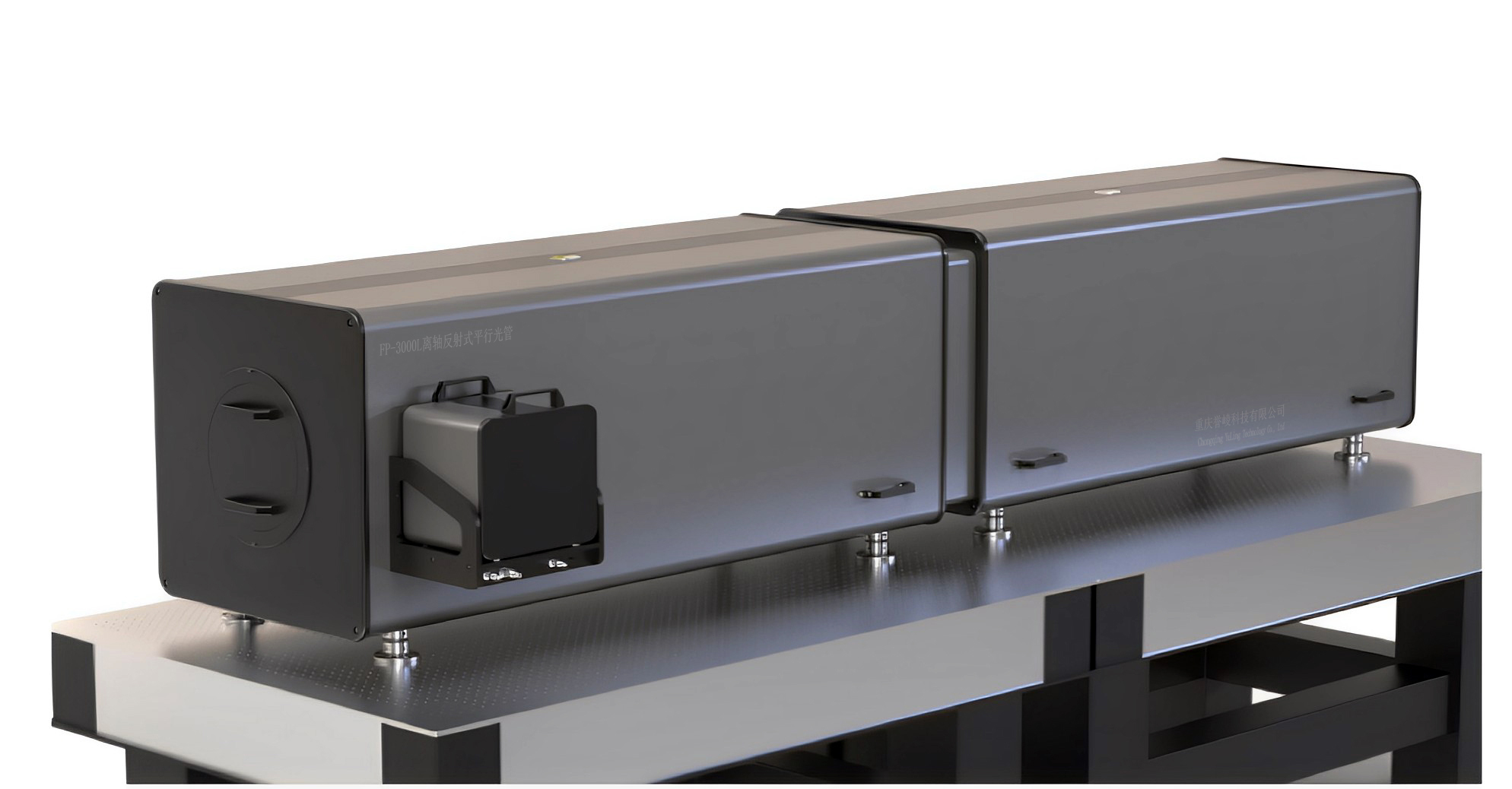

Only by addressing these challenges can technological progress be achieved. The high-precision off-axis collimator series launched by Chongqing Yuling Technology Co., Ltd. (official website:https://chinacqyl.com) stands out with three core advantages—”ultra-precision, wide adaptability, and high stability”—and has become the preferred equipment for precision optical testing. This equipment can simulate infinite-distance targets, perform visible light axis calibration, imaging system testing, and optical parameter measurement. As an instrument mainly used to obtain large-aperture parallel light beams, it has a wide range of applications: by selecting different reticles, appropriate resolution charts, and equipping with reading microscopes or measuring microscopes, it can measure the intercept and focal length of prisms, plane mirrors, and various objective lenses, and judge their imaging quality based on the images of resolution patterns; with suitable star test charts and observation microscopes or foreoptics, it can evaluate the image quality of lenses, prisms, plane mirrors, and various objective lenses; combined with dedicated reflectors and micrometric eyepieces, it can measure the straightness of guide rails and large planes. Based on these advantages, off-axis collimators can seamlessly adapt to the testing needs of optical equipment ranging from miniature UAV pods to large-scale spaceborne remote sensing cameras, and have become indispensable testing equipment in multiple key fields, playing an important role in core high-end manufacturing and people’s livelihood scientific research. Two types are available to meet different usage needs: Off-Axis Cassegrain Collimators and Off-Axis Newtonian Reflective Collimators.

1. Off-Axis Cassegrain Collimators: Customizable models include FP-3000LK; FP-5000LK-300; FP-10030LK, etc.

2. Off-Axis Newtonian Reflective Collimators: Customizable models include FP-500L; FP-1000L; FP-1000L-150; FP-1500L; FP-1500L-200; FP-2000L, etc.

Collimators, with their unwavering “light ruler,” define the precision origin of modern optical technology. As market demand for high-precision optical equipment grows explosively, requirements for the accuracy and efficiency of test and calibration equipment are also rising. Off-axis collimators provide core support for improving the quality and efficiency of the optical equipment industry through “standardized testing.” They are not only tools but also benchmark transmitters spanning the microcosm and deep space, connecting manufacturing and exploration, measuring the ultimate boundaries of human precision engineering in every microradian of optical axis pointing.