In security surveillance patrols at night, medical temperature screening, and spaceborne remote sensing surface detection, infrared cameras consistently serve as “infrared eyes”. The precision of these “eyes” in capturing targets hinges on lens calibration accuracy—minor optical axis deviations or imaging distortions may distort infrared images and cause critical information to be missed. How to ensure clear infrared imaging and precise optical axis alignment? The emergence of The Off-Axis Parabolic Collimators offers a breakthrough solution to this predicament. Their unique design and superior performance are now laying a solid foundation for the precision of infrared optical systems.

Infrared photons, with their lower energy, are more susceptible to interference from internal reflections and scattered light within the system. In coaxial systems, multiple reflections from lenses generate significant stray light, directly compromising calibration accuracy. However, off-axis systems employ a design where the primary and secondary mirrors are not aligned in a straight line. This seemingly simple “offset” configuration fundamentally resolves the core challenge of infrared calibration: stray light interference.

Chongqing Yuling Technology Co., Ltd. (official website: https://chinacqyl.com) designed The Off-Axis Parabolic Collimator, which provides a “standard ruler” for the fine-tuning of infrared camera lenses with its unique optical structure and technical advantages:

This off-axis design optimizes light path by allowing stray reflections to naturally exit the system. The quartz primary mirror paired with an “aluminum-silicon protective” coating achieves over 85% reflectivity, effectively minimizing both light energy loss and stray light interference. Its optical performance metrics are particularly impressive: a surface accuracy RMS below 1/20λ (λ = wavelength) ensures efficient infrared light transmission and collimation precision, while a parallelism of ≤5″ (≈0.0014°) generates near-ideal parallel beams. This capability accurately simulates infinity targets, a critical factor for evaluating lens depth of field and imaging quality in infrared cameras.

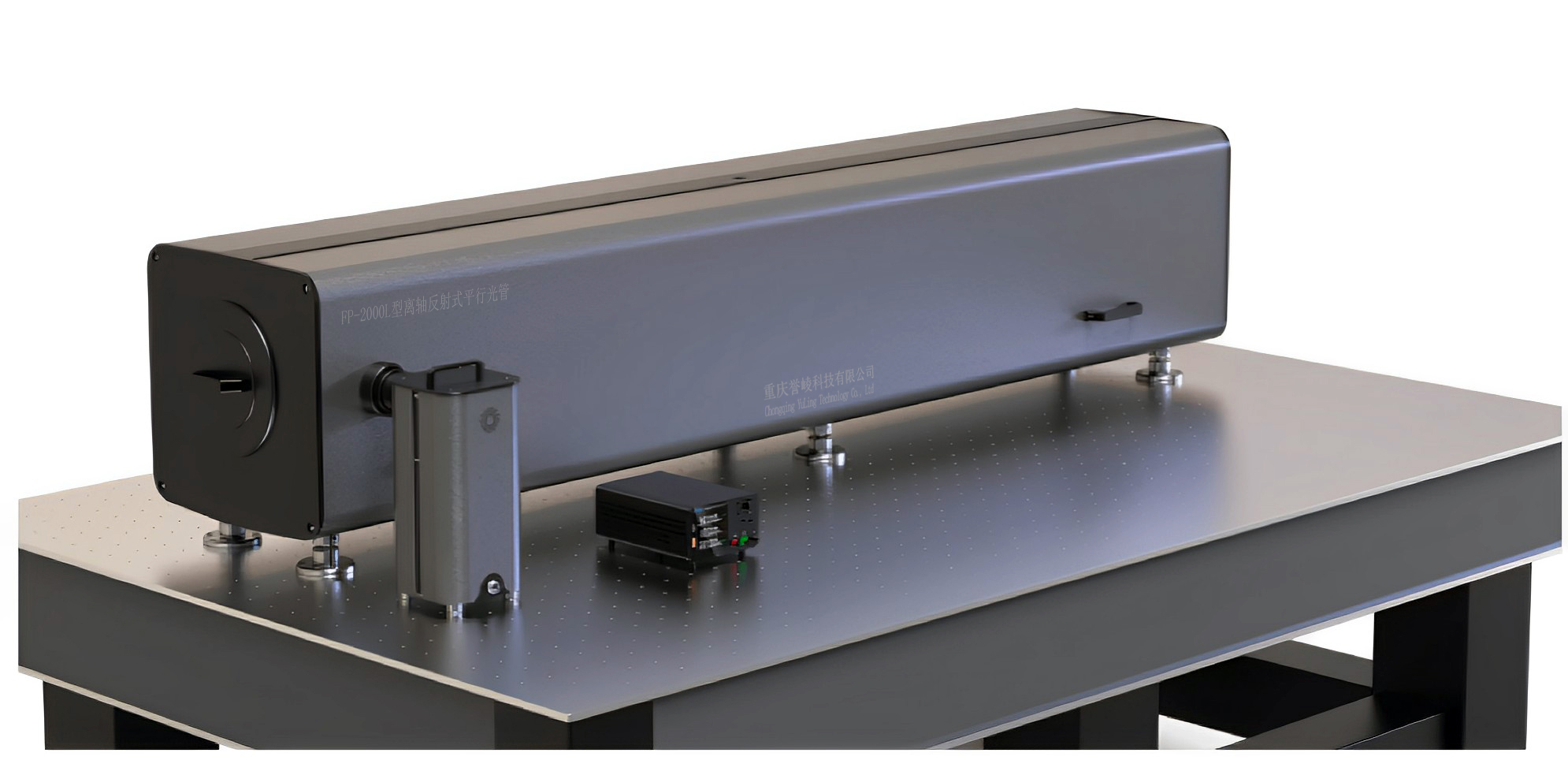

Product Recommendation: Model FP-2000L

Multiple models are available for customization based on different requirements:

FP-500L; FP-1000L; FP-1000L-150; FP-1500L; FP-1500L-200; FP-2000L, etc.

The core of fine-tuning infrared camera lenses lies in solving three key issues: “inaccurate optical axis,” “unclear imaging,” and “imprecise distance measurement.” The Off-Axis Parabolic Collimators form a complete calibration closed-loop through three core functions:

- Simulate infinity target and calibrate the “line-of-sight reference”

Infrared cameras are primarily used for long-distance detection—for example, identifying targets several kilometers away in border security or capturing surface images from an altitude of 10,000 meters in aerospace remote sensing. This requires lenses to achieve exceptional imaging precision for “infinity targets.” The Off-Axis Parabolic Collimators generate parallel light beams with ultra-low divergence angles, converting target signals into optical images of infinity targets. This effectively enables infrared lenses to “visualize” scenes thousands of kilometers away within a laboratory environment. By analyzing the captured target images, technicians can assess the lens’s focusing accuracy for long-distance targets, thereby preventing the “distant target blurring” issue encountered in practical applications.

- Precise adjustment of optical axis to eliminate potential deviation

Infrared cameras are often integrated with visible light or laser systems (e.g., security devices combining infrared imaging with laser ranging). Any misalignment between optical axes can cause discrepancies between the “observed target” and the “measured distance.” A key advantage of The Off-Axis Parabolic Collimators lies in their ability to perform high-precision calibration for multi-axis systems. With a parallelism accuracy of ≤5″, technicians can accurately identify optical axis deviations in infrared lenses. By capturing a broad-spectrum cross target from the collimator and using image processing algorithms to extract the spot centroid, the offset angle is calculated for calibration. This pixel-level precision far exceeds the 0.1mrad (≈20″) error threshold commonly accepted in infrared systems.

- Check image quality and optimize the “image quality limit”

The clarity and contrast of infrared imaging directly determine detection effectiveness, while lens distortion and aberrations significantly impact image quality. The Off-Axis Parabolic Collimators enable comprehensive inspection of infrared lens imaging quality through precise light field control within a 1.3° field of view (FOV). By illuminating a standard resolution target chart with high-quality parallel light, technicians can analyze the clarity distribution of the target image to assess the lens’s aberration levels. Combined with the ultra-high surface accuracy of the primary mirror (1/20λ), this method eliminates interference from inherent errors of the collimator itself, ensuring that test data accurately reflects lens performance and provides precise references for subsequent optical structure optimization.

In summary, The Off-Axis Parabolic Collimators demonstrate three unique advantages in the fine-tuning of infrared lenses:

First, they provide superior stray light control. The off-axis design completely eliminates the “central occlusion” effect in coaxial systems, significantly improving calibration accuracy for weak infrared signals.

Second, they offer excellent broadband adaptability. The combination of a quartz primary mirror and high-reflection coating perfectly matches the optical characteristics of the infrared band while supporting multi-band calibration for visible light and lasers, enabling “multi-purpose functionality.”

Third, they balance high precision with stability. With 1/20λ surface accuracy and ≤5″ parallelism, they ensure reliable micron-and angstrom-level calibration for infrared lenses. The 12V30W stable light source design guarantees consistent performance over long-term use.

From the “space eye” of aerospace remote sensing to the “night patrol sentinel” for public safety, the precision enhancement of infrared cameras has always relied on breakthroughs in optical calibration technology. The Off-Axis Parabolic Collimators , with its unique off-axis design and exceptional optical performance, has become the “standard tool” for fine-tuning infrared lenses. It not only drives the precision upgrade of infrared optical equipment but also provides core support for the implementation of infrared technology across various fields. As infrared technology evolves toward miniaturization and high resolution, this “master of fine-tuning” will continue to shine in more advanced domains.