Products Brief:

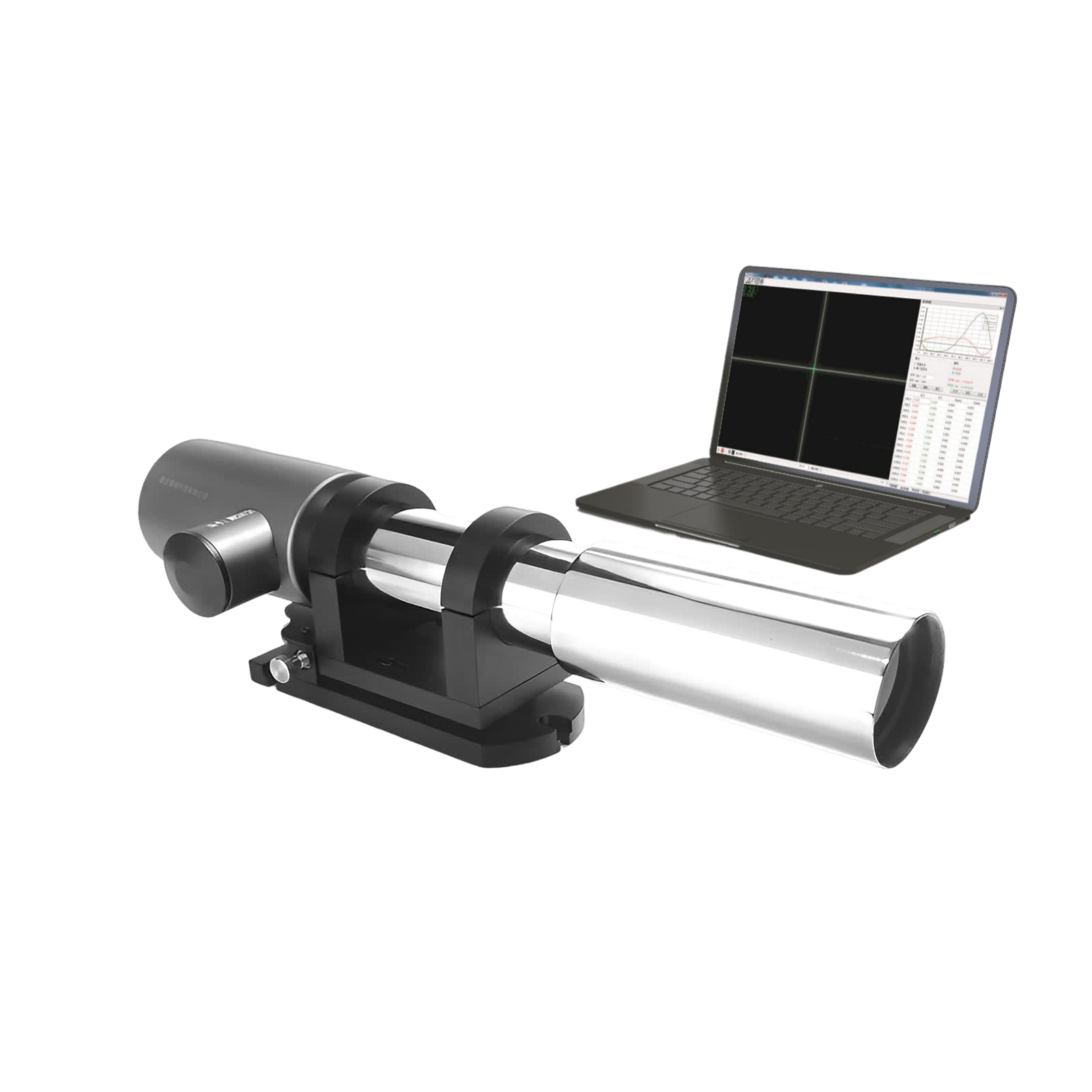

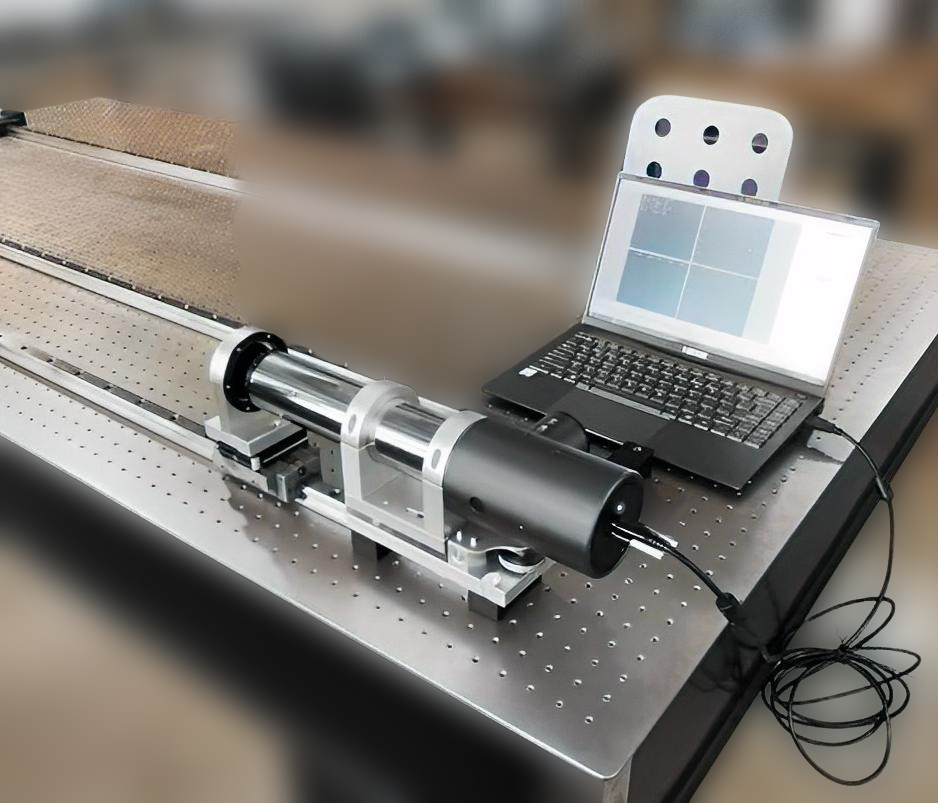

Digital Dual-Axis Photoelectric Autocollimator The dual-axis photoelectric autocollimator (also known as an electronic autocollimator) is a next-generation high-precision measuring instrument that integrates an autocollimator with high-resolution image sensors and state-of-the-art digital image processing technology. It enables simultaneous angle measurement in both X and Y directions, making it an ideal instrument for precision mechanical manufacturing, optical assembly, machine tools, precision guide rails, and precision surface plates. Our company offers a series of high-precision products, including models with resolutions of 1″, 0.5″, 0.3″, 0.2″, and 0.1″. These devices feature advantages such as portability, high accuracy, and excellent stability.

The dual-axis photoelectric autocollimator consists of components including an electronic eyepiece, an objective lens tube, a two-dimensional adjustment base, a reflector, and control measurement software. The measurement software, running on a display controller, can display the reflected crosshair image captured by the electronic eyepiece in real time and accurately measure the current position coordinates of the reflected image. The main unit communicates with a PC via a USB 2.0/3.0 interface, ensuring ease of use. The built-in long-life semiconductor LED light source provides a lifespan of tens of thousands of hours.

The series features a compact design, offering users a cost-effective solution for high-precision angle measurement and detection. By selecting optional accessories and corresponding software analysis modules, users can perform measurements in various applications, including angle, straightness, perpendicularity, parallelism, and flatness. This makes the dual-axis photoelectric autocollimator an ideal replacement for traditional optical autocollimators in applications such as precision mechanical manufacturing, optical processing, and metrology laboratories.

Product Use:

- Measurement of the deflection angle of the reflective surface

- Beam deflection angle measurement

- Measurement of geometric accuracy such as straightness, perpendicularity, flatness, parallelism, and parallelism

- Measurement of turntable positioning accuracy, radial/inclination runout, etc

- Positioning and installation of precision machinery

- Optical product assembly, various prism angle measurement

- Precise angle measurement or dynamic monitoring

- Verification and calibration of other testing equipment or tools

Product Features:

- Automatic Curve Plotting and Error Calculation

- Simultaneous Dual-Axis X and Y Measurement for Improved Efficiency

- Real-Time Electronic Eyepiece Technology to Minimize Visual Alignment Errors

- High-Resolution Photoelectric Detector for Enhanced Measurement Accuracy

- Long-Life LED Light Source System for Durability and Reliability

- Compatibility with Various Accessories and Measurement Modules to Meet Diverse Requirements

- Multiple Data Processing Methods with Standardized Excel Report Generation for Easy Review

- Available in Multiple Specifications to Suit Different Measurement Objectives

- Multi-Language Support (Chinese, English, Russian, and Korean)

Measuring Principle:

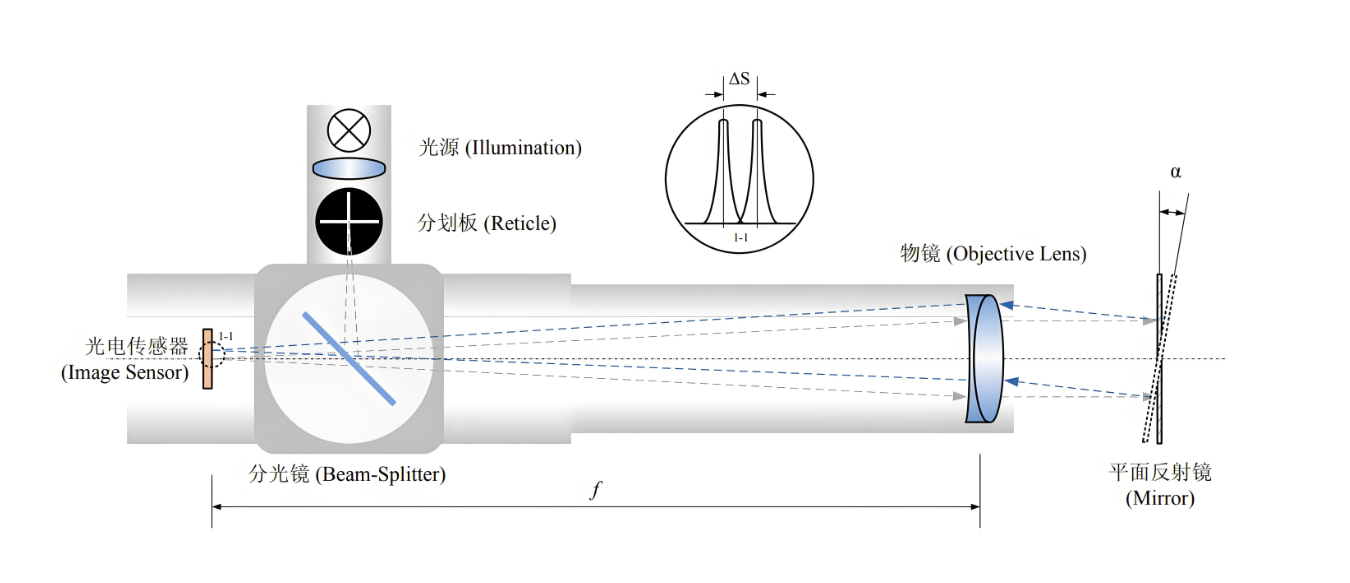

An autocollimator is an instrument that measures small angular deviations using the principle of optical autocollimation.Principle of Autocollimation: Light passes through a reticle positioned at the focal plane of the objective lens, forming parallel light rays via the objective lens. These parallel rays are reflected back by a mirror perpendicular to the optical axis, and after passing through the objective lens again, they form an image of the reticle on the focal plane, coinciding with the original reticle markings.

An autocollimator typically consists of a light source, reticle, beamsplitter, objective lens, reflector, and eyepiece. In photoelectric autocollimators, optical sensors replace the eyepiece for detecting the reticle image (refer to the schematic diagram above).

In optical autocollimators, measurements are performed manually through visual observation combined with mechanical micrometer devices. In photoelectric autocollimators, the reflected reticle image is received by a photoelectric sensor. The light source projects the reticle, positioned at the focal plane of the objective lens (focal length = f), into infinity (collimated light emission). The collimated light, reflected back by a plane mirror, passes through the objective lens again and forms an image on the detection surface of the photoelectric sensor, which is also at the objective’s focal plane in a confocal system.

When the reflector tilts by an angle α, the reflected reticle image experiences a displacement ΔS on the photoelectric sensor (as shown in the diagram), corresponding to an angular deviation of 2α. By precisely measuring the value of ΔS, the tilt angle of the plane mirror can be accurately calculated.

The above-specified accuracies are based on metrological verification conditions. Actual performance may vary depending on environmental factors and should be evaluated accordingly.For general measurements, preheating is not required. However, for high-precision measurements, the instrument should be powered on and preheated for no less than 15 minutes. For metrological verification, the instrument must be kept at a constant temperature and left to stabilize for no less than 24 hours.

This series of photoelectric autocollimators utilizes high-precision photoelectric sensors and operates on standard PCs. The system requires a 64-bit Windows 7 or higher operating system, with a CPU no lower than a 4th-generation Intel Core i3 and a clock speed of no less than 2.3 GHz. For high-precision models, higher PC configurations are recommended.

The above specifications represent only part of our product range. For special requirements, please contact us; customization is supported.

Standard Configuration:

- Dual-Axis Photoelectric Autocollimator Main Unit (including two-dimensional adjustment base) …… 1 unit

- Standard Reflector …… 1 piece

- USB Data Transfer Cable ……1 piece

- Autocollimator Control Software (including straightness measurement module + error reference module + real-time straightness display module) ……1 set

Optional Configuration:

Laptop (for dedicated use, with Windows 7 or Windows 10 64-bit system, Intel Core i3 or higher processor)

Dedicated Tripod

Optical Right Angle Indicator (2″, 5″, 10″, 15″, 30″)

Prism Adjustment Platform

Laser-Assisted Aiming Device (Rechargeable Version)

Wireless Data Collector (Touchscreen Version)

Multi-Faceted Prism (8, 12, 17, 23, 24, 36 faces, Grade 1 or Grade 0)

Multi-Tooth Dividing Head

Adjustable Bridge Plate (for measuring platform flatness)

Perpendicularity and Parallelism Software Module

Flatness Software Module

Circular Dividing Software Module

One-to-Two Autocollimator Software Module

One-to-Four Autocollimator Software Module

One-to-Many Autocollimator Software Module

Dedicated Adjustment Platform

Special Tips:

The above-specified accuracies are based on metrological verification conditions. Actual performance may vary depending on environmental factors and should be evaluated accordingly.For general measurements, preheating is not required. However, for high-precision measurements, the instrument should be powered on and preheated for no less than 15 minutes. For metrological verification, the instrument must be kept at a constant temperature and left to stabilize for no less than 24 hours.

This series of photoelectric autocollimators utilizes high-precision photoelectric sensors and operates on standard PCs. The system requires a 64-bit Windows 7 or higher operating system, with a CPU no lower than a 4th-generation Intel Core i3 and a clock speed of no less than 2.3 GHz. For high-precision models, higher PC configurations are recommended.

The above specifications represent only part of our product range. For special requirements, please contact us; customization is supported.