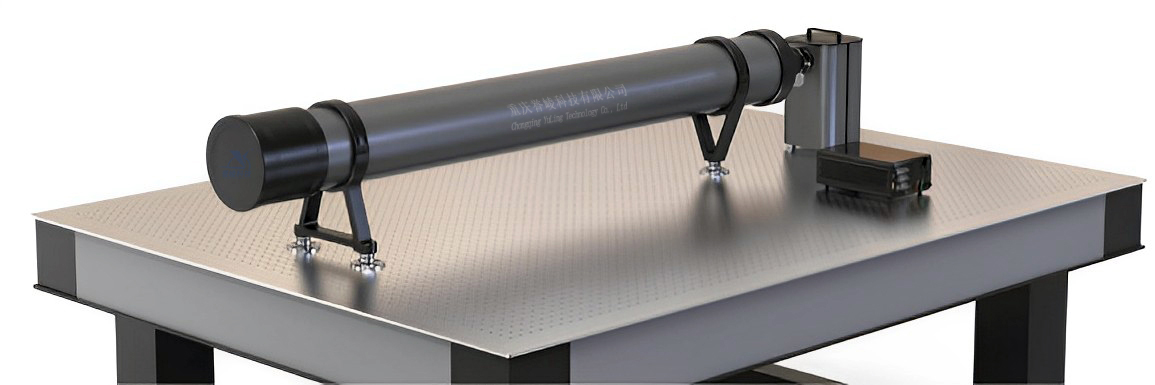

High-Precision Optical Beam Generation

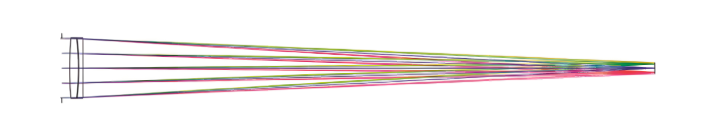

The YuLing collimator employs a 1600 mm focal length system with a Φ148 mm effective aperture to deliver stable, large-diameter parallel beams. Its optical design ensures ≤10″ beam parallelism and ≤0.9″ resolution, meeting laboratory-grade alignment standards. This instrument serves as a reference source for optical material uniformity testing and optical mount calibration, providing accurate simulation of parallel illumination for inspection and adjustment processes.

Accurate Collimator Lens Performance

The precisely ground collimator lens operates across 380–780 nm, covering the full visible spectrum with excellent transmittance. With a field of view ≥1° and focal accuracy within ±1%, it ensures stable, distortion-free imaging. The optical tube is made of reinforced alloy to minimize mechanical stress, ensuring long-term stability during extended measurement or production cycles in optical laboratories and manufacturing facilities.

Flexible System Configuration

When paired with optional modules such as reading microscopes, star pattern plates, and front mirrors, the pinhole collimator expands into a multifunctional optical testing system. It supports lens resolution analysis, mirror flatness testing, and optical straightness verification for high-precision components. With its modular structure, it easily integrates into existing metrology setups, improving testing efficiency and adaptability for research or industrial environments.

Product Advantages

Superior Beam Uniformity And Precision

The advanced optical assembly maintains excellent coaxial precision between optical and mechanical axes. Each collimator undergoes alignment verification to ensure ≤10″ beam parallelism, offering consistent reference standards for optical inspection and calibration in demanding testing environments.

High Transmission And Broad Spectrum Operation

The collimator lens is coated with multilayer anti-reflection films, optimizing transmittance across the 380–780 nm range. This provides uniform illumination and minimal chromatic distortion, enabling clear resolution pattern observation and improved image evaluation accuracy under varying light conditions.

Professional Collimator Manufacture And Durability

As a specialized collimator manufacture, YuLing Technology follows rigorous production control—covering lens machining, coating, and final assembly. Each product is tested for wavefront accuracy and mechanical alignment, ensuring reliability and precision. The robust construction resists vibration, temperature drift, and contamination, extending service life for continuous industrial operation.

Applications:

The F-1600 Collimator Tube is an instrument used to generate a large-diameter parallel light beam, with a wide range of applications. By selecting different reticle plates and pairing it with various accessories such as observation microscopes, front mirrors, it can be used for the following purposes:

- As a fundamental tool for optical instrument alignment and adjustment.

- With the selection of a Borosilicate plate and paired with a reading microscope or measuring microscope, it can be used for measuring the intercepts and focal lengths of lenses and various objective lenses.

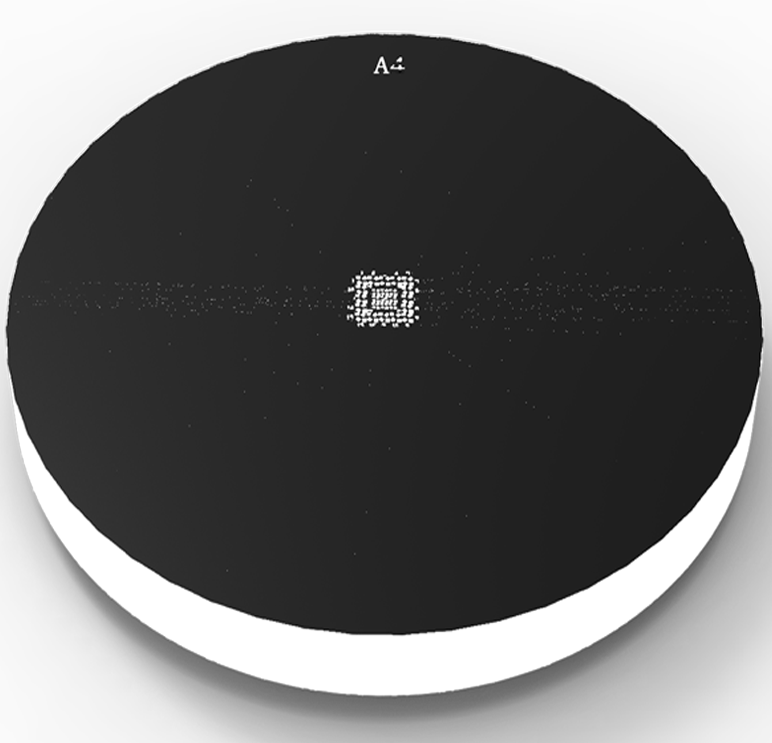

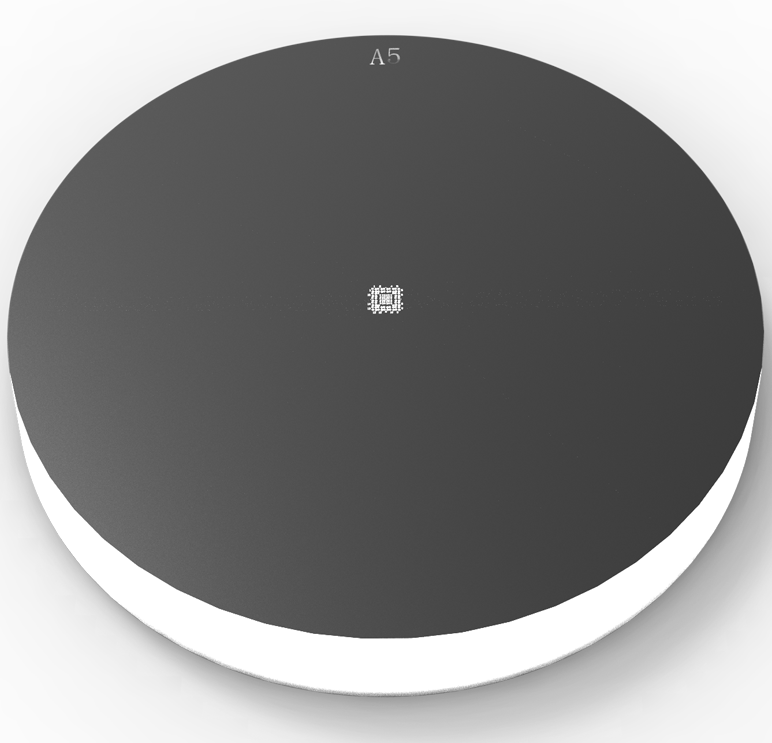

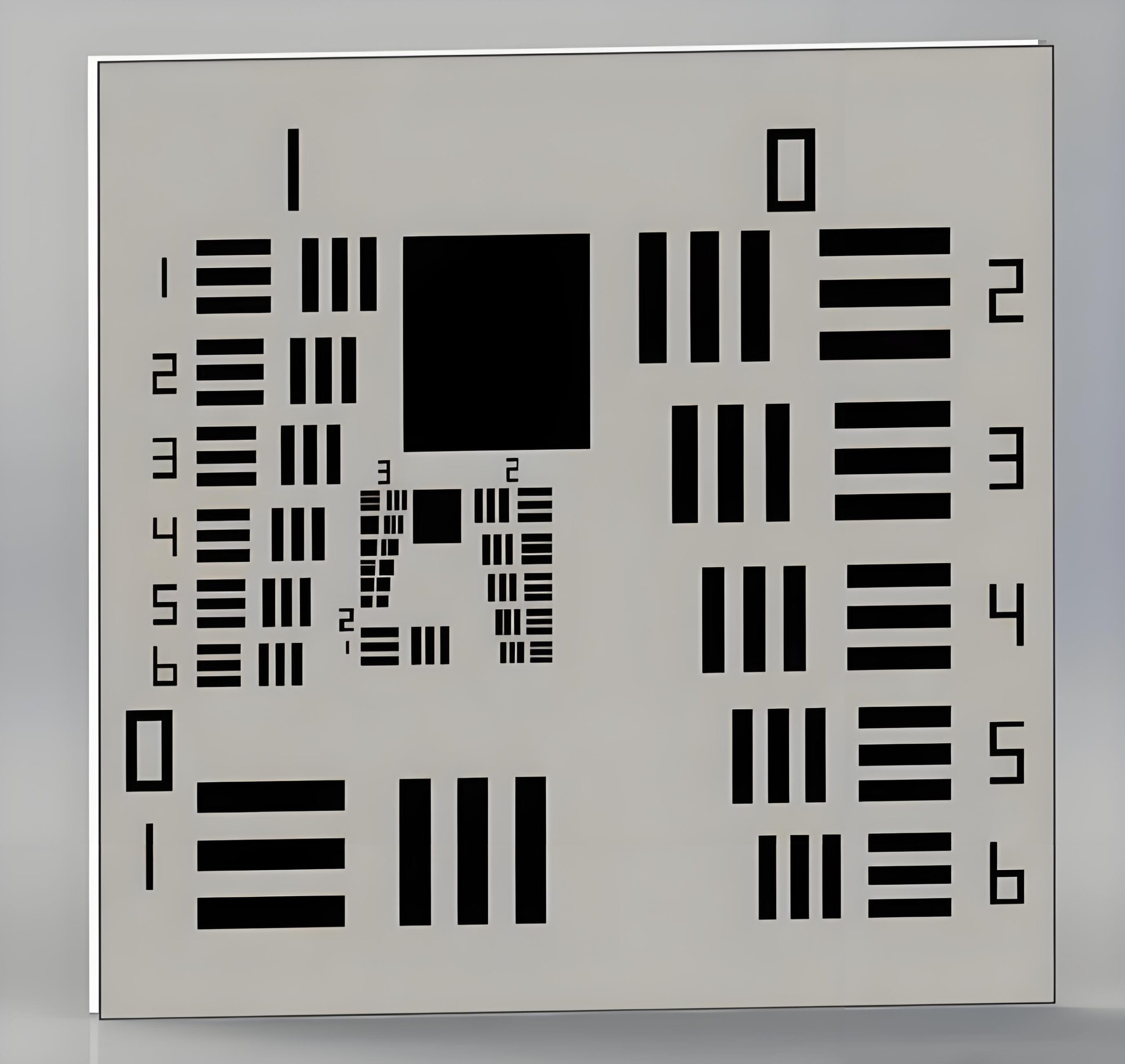

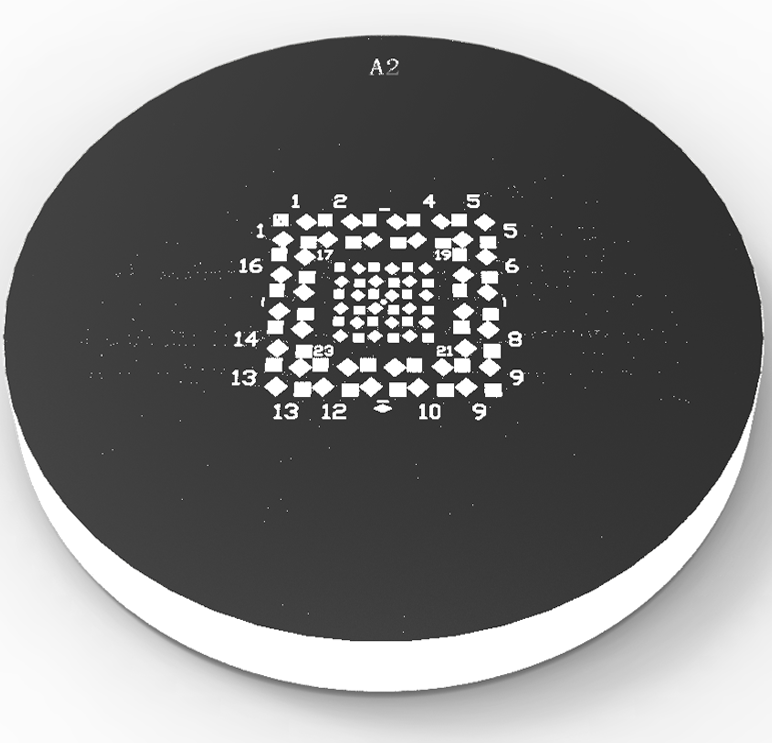

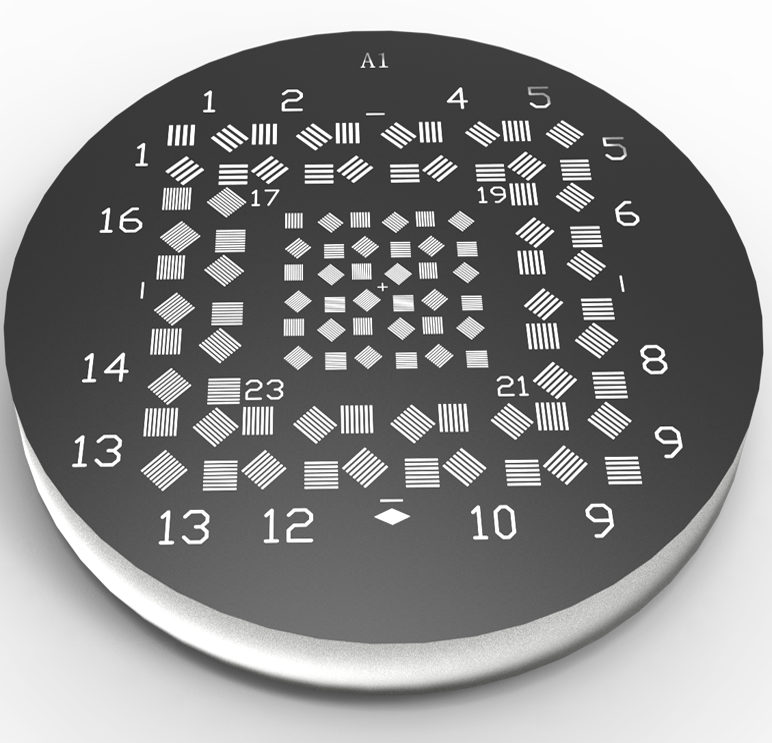

- With the selection of an appropriate resolution plate, and paired with an observation microscope and front mirror, it can be used for determining the resolution of lenses, prisms, plane mirrors, and various objective lenses, as well as for assessing image quality by observing resolution patterns.

- With the selection of an appropriate star pattern plate and paired with an observation microscope and front mirror, it can be used to evaluate the image quality of lenses, prisms, plane mirrors, and various objective lenses.

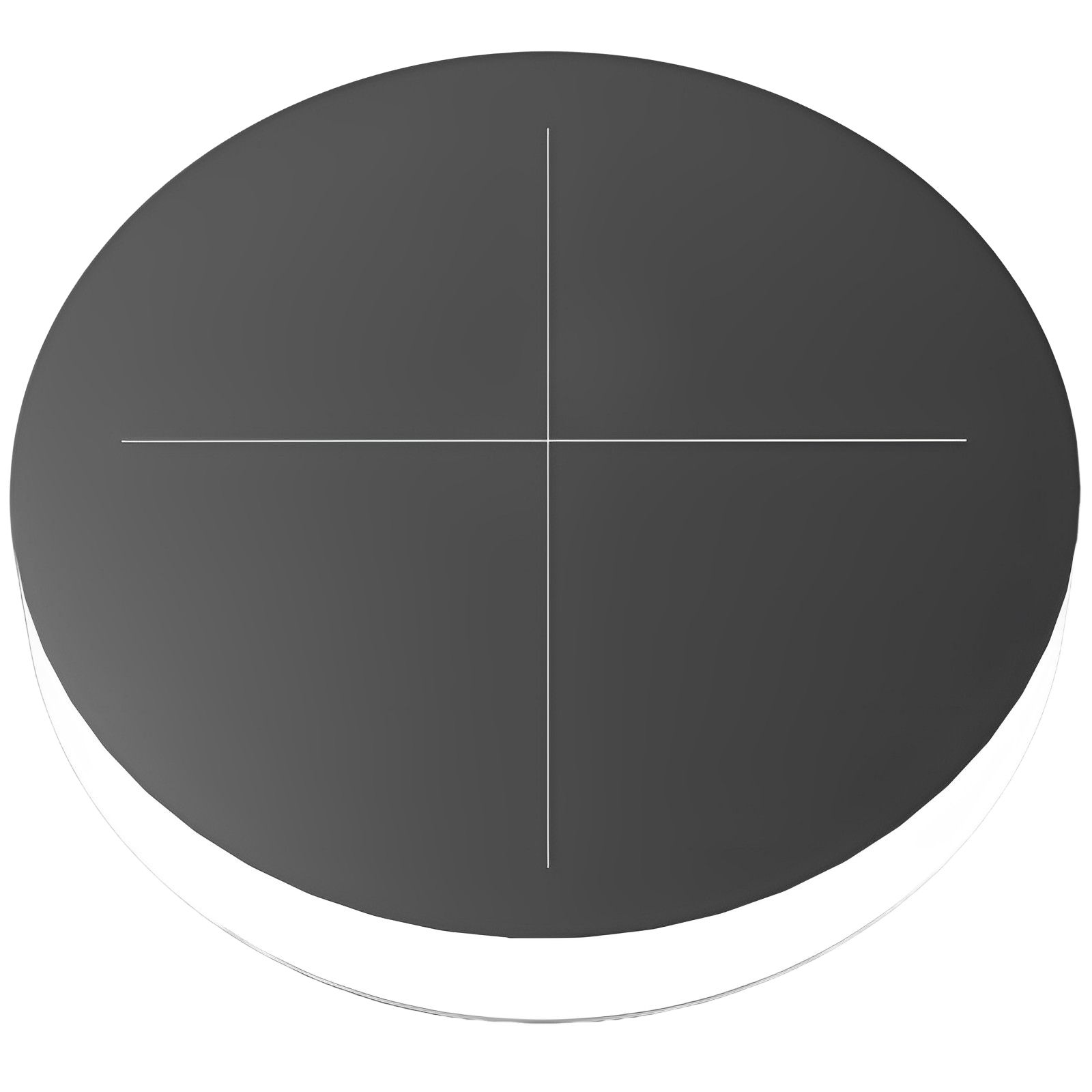

- By equipping the instrument with specialized mirrors and measuring eyepieces, it can be used to measure straightness or flatness deviations of rails and large flat surfaces.

- As a tool for aiming at long-distance targets.

Additionally, the F Series Collimator Tubes are essential test reference components for optical material uniformity checks and the calibration of various optical mounts. Therefore, they are commonly used in the production, research, and teaching of optical instruments.

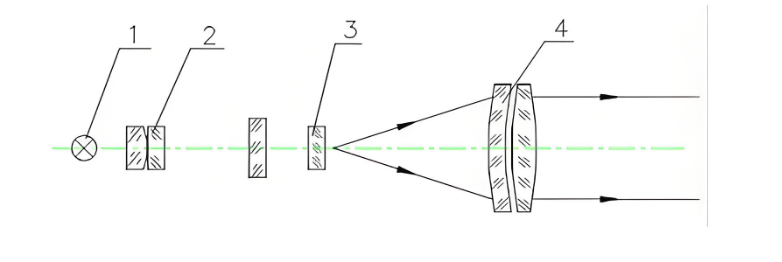

Working Principle:

As shown in the figure below, the reticle serving as the target is uniformly illuminated by light source 1 through various color filters 2. If the reticle 3 is correctly positioned at the focal plane of the objective lens 4, the light emitted from the objective lens forms a parallel light beam, which is equivalent to light originating from infinity.

Optical path diagram:

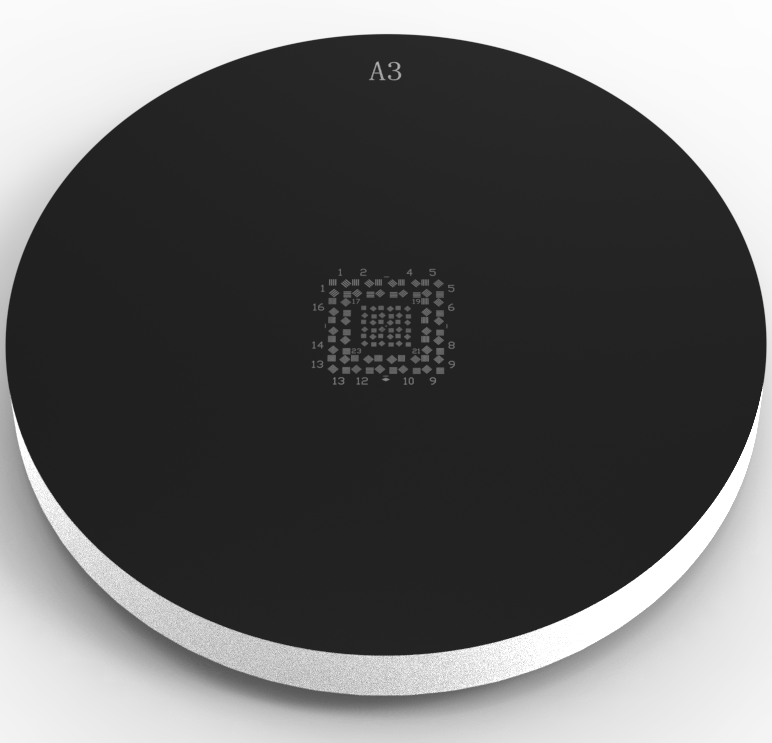

Standard Components:

Collimator Main Unit: 1 piece(Equipped with a fine-tuning foot bracket)

Filters: 2 pieces (Orange, center wavelength 600nm; Green, center wavelength 532nm)

Attenuator: 1 piece (Neutral Attenuator 430–730nm)

Visible Reticles: 13 piece(Crosshair Reticles*1,Resolution Reticles*6 :1#2#/3#/4#/5#/USAF1951,Star Point Reticles*5: 0.1/.01/0.2/0.02/0.05,Porro Board*1)

DC voltage stabilizing power supply: 1 piece (Output voltage:0-30V,Output current:0-5A)

Light Source Assembly: 1 set (12V30W halogen light source)

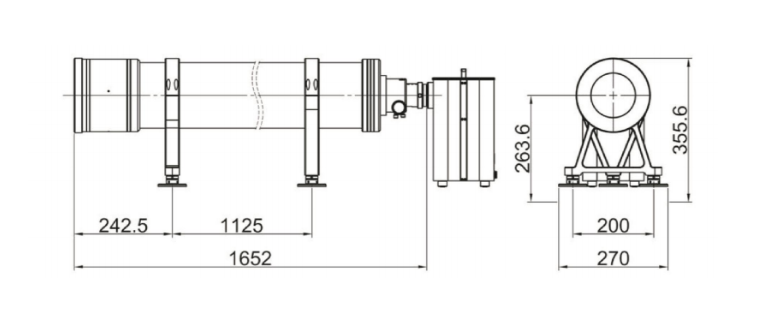

External dimensions:(Unit: mm)

About Us

YuLing Technology, headquartered in Chongqing, China, designs and manufactures precision optical and photoelectric instruments. With an R&D base in Xi’an, the company focuses on collimators, autocollimators, optical benches, and customized calibration systems. YuLing’s integrated capabilities include optical design, mechanical engineering, and control systems. Its instruments are widely used in aerospace, defense, and metrology industries. Committed to quality and integrity, YuLing ensures that each product meets international precision standards, offering reliable performance, professional service, and long-term customer partnerships.

Contact YuLing to request specifications or discuss your custom optical testing needs today!

FAQ – Frequently Asked Questions

How accurate is the YuLing collimator in beam alignment?

Each unit achieves ≤10″ beam parallelism verified by interferometric calibration to maintain consistent optical precision.

What is the working wavelength range of the collimator lens?

It operates across 380–780 nm, suitable for all visible light optical testing and imaging applications.

Can the pinhole collimator module be customized?

Yes, YuLing offers custom reticle plates, aperture configurations, and optical accessories for different calibration tasks.

What is the lead time for delivery?

Standard production and inspection require approximately four to six weeks depending on custom configurations.

Does YuLing provide maintenance and recalibration services?

Yes, professional recalibration, cleaning, and component replacement services are available to ensure long-term precision.