Precision Optical Beam Generation

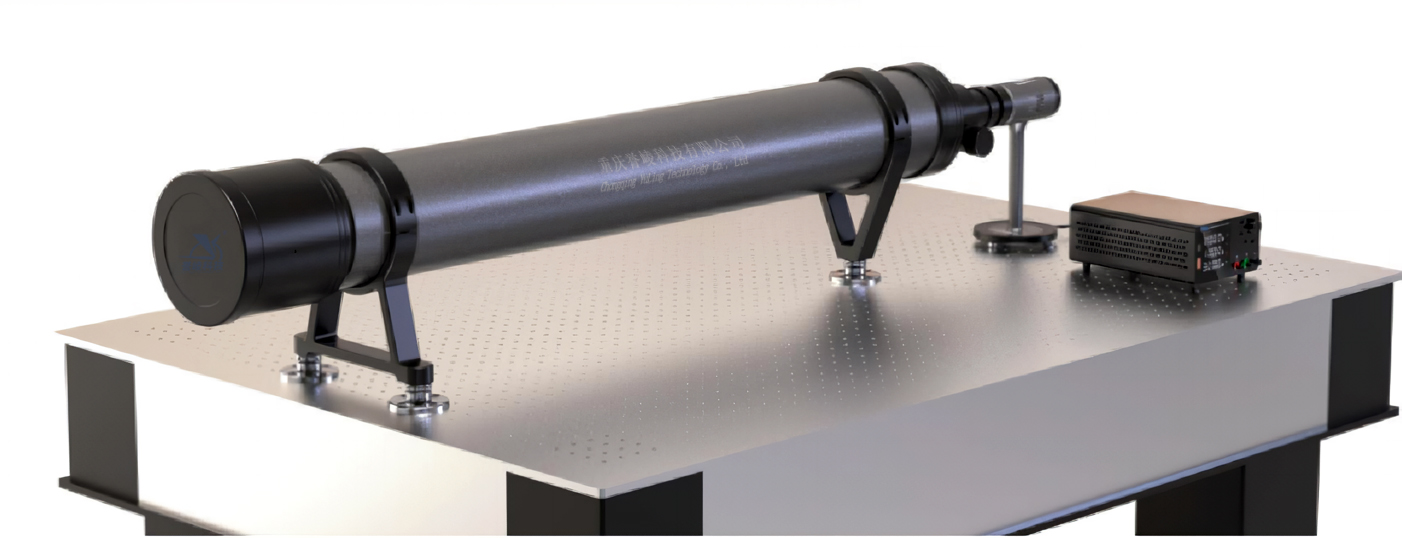

The YuLing collimator produces a stable parallel light field using a 1300 mm focal system with a Φ130 mm effective aperture. It provides ≤10″ parallelism and ≤1″ resolution, serving as a fundamental optical reference in testing, calibration, and research. By integrating adjustable reticle plates, the system simulates ideal light paths for optical material uniformity inspection, lens alignment, and optical instrument calibration in laboratories or production lines.

Accurate Collimator Lens Construction

Engineered with precision-ground glass and coated optics, the collimator lens maintains focus accuracy within ±1%. The 380–780 nm working wavelength range ensures compatibility with most visible light applications. The rigid optical tube minimizes deformation, while thermal compensation preserves beam parallelism during extended operation, ensuring consistent accuracy in metrology and imaging evaluations.

Comprehensive Testing Adaptability

When configured with optional accessories such as reading microscopes, front mirrors, or star pattern plates, the pinhole collimator enables multiple measurements—focal length, resolution, and surface quality assessment. Its modular interface allows quick conversion for different optical analyses, including lens quality, mirror flatness, and prism imaging.

Product Advantages

High-Definition Parallel Beam Output

The advanced optical alignment system provides stable, large-diameter collimation for complex testing environments. Each collimator is calibrated for precise beam uniformity, ensuring repeatable results across optical inspection and adjustment tasks.

Superior Light Transmission And Durability

The multi-layer coated collimator lens guarantees high transmission and minimal reflection loss across the visible spectrum. With aluminum alloy construction and precision sealing, the system resists contamination, vibration, and thermal distortion during continuous operation.

Professional Collimator Manufacture Quality Assurance

YuLing Technology’s position as a dedicated collimator manufacture ensures strict quality control from design to assembly. Each unit undergoes optical axis verification and mechanical alignment testing to meet laboratory standards, delivering reliability and long service life.

Applications:

The F-1300 Collimator Tube is an instrument used to generate a large-diameter parallel light beam, with a wide range of applications. By selecting different reticle plates and pairing it with various accessories such as observation microscopes, front mirrors, it can be used for the following purposes:

- As a fundamental tool for optical instrument alignment and adjustment.

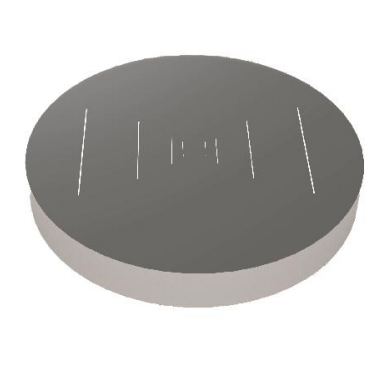

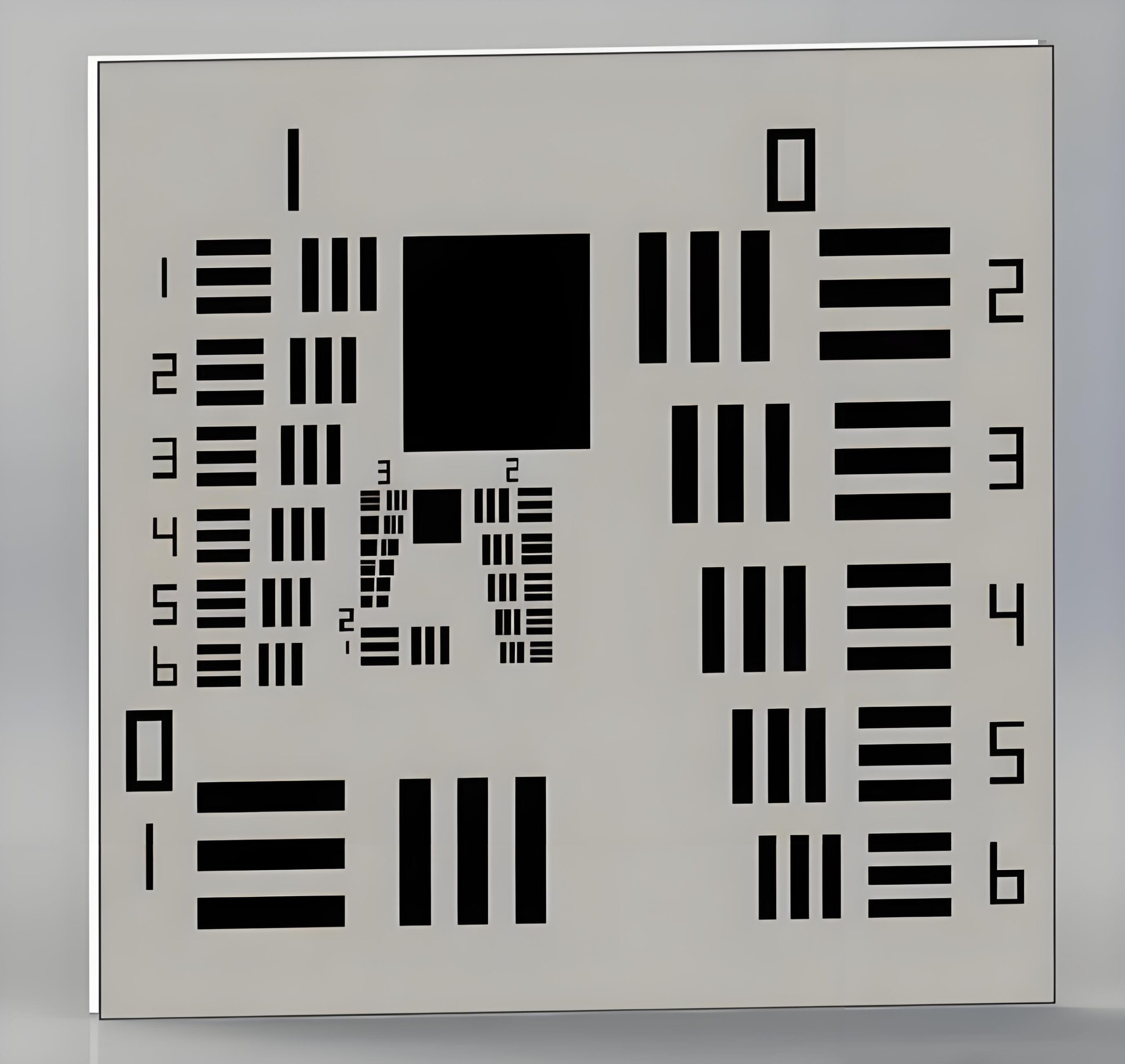

- With the selection of a Borosilicate plate and paired with a reading microscope or measuring microscope, it can be used for measuring the intercepts and focal lengths of lenses and various objective lenses.

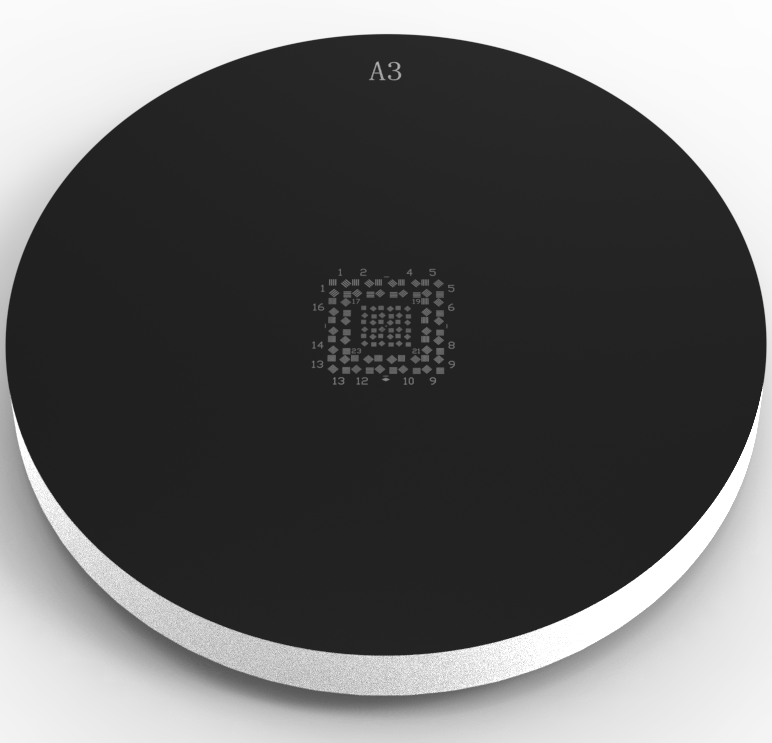

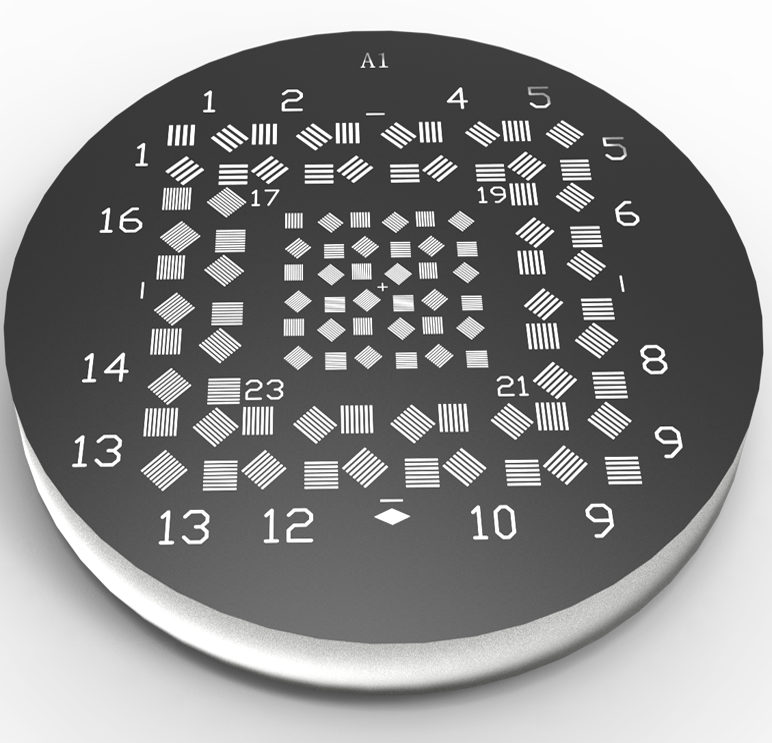

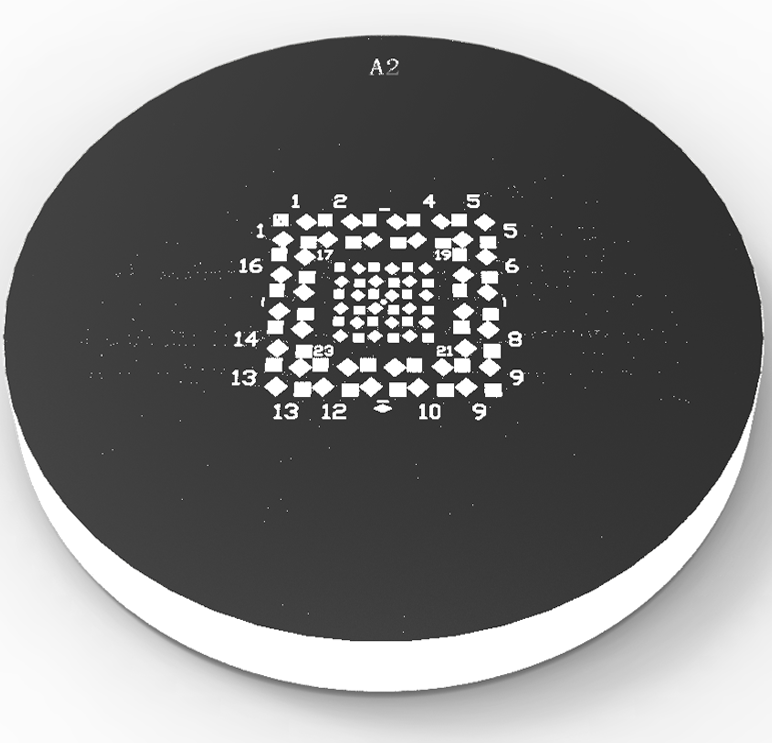

- With the selection of an appropriate resolution plate, and paired with an observation microscope and front mirror, it can be used for determining the resolution of lenses, prisms, plane mirrors, and various objective lenses, as well as for assessing image quality by observing resolution patterns.

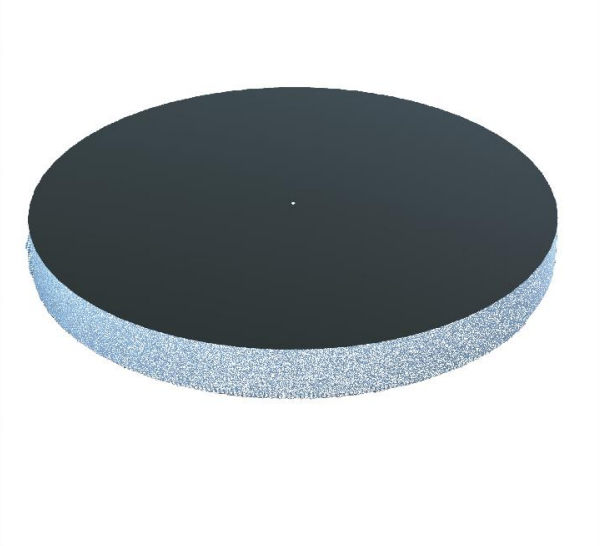

- With the selection of an appropriate star pattern plate and paired with an observation microscope and front mirror, it can be used to evaluate the image quality of lenses, prisms, plane mirrors, and various objective lenses.

- By equipping the instrument with specialized mirrors and measuring eyepieces, it can be used to measure straightness or flatness deviations of rails and large flat surfaces.

- As a tool for aiming at long-distance targets.

Additionally, the F Series Collimator Tubes are essential test reference components for optical material uniformity checks and the calibration of various optical mounts. Therefore, they are commonly used in the production, research, and teaching of optical instruments.

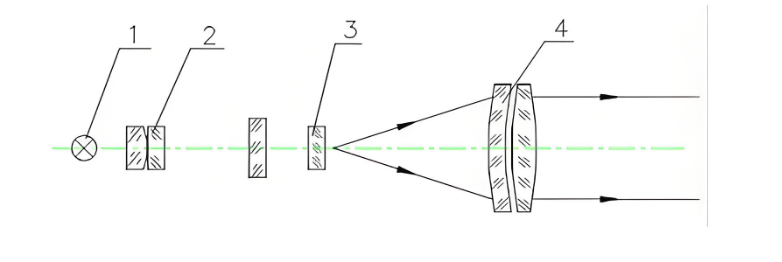

Working Principle:

As shown in the figure below, the reticle serving as the target is uniformly illuminated by light source 1 through various color filters 2. If the reticle 3 is correctly positioned at the focal plane of the objective lens 4, the light emitted from the objective lens forms a parallel light beam, which is equivalent to light originating from infinity.

Optical path diagram:

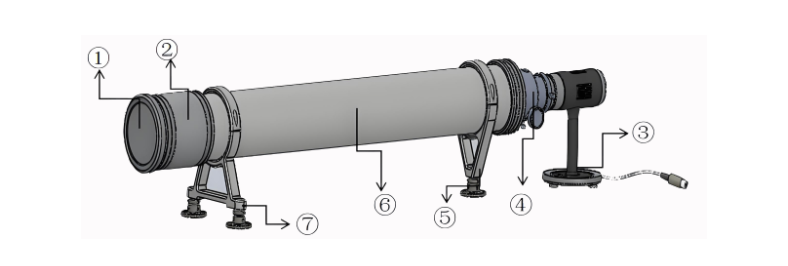

Product structure:

① Lens Cap

② Objective Lens Assembly

③ Light Source

④ Focusing Base

⑤ Rear Support Assembly

⑥ Collimating Tube

⑦ Front Support Assembly

Standard Components:

Collimator Main Unit: 1 piece(Equipped with a fine-tuning foot bracket)

Filters: 2 pieces (Orange, center wavelength 600nm; Green, center wavelength 532nm)

Attenuator: 1 piece (Neutral Attenuator 430–730nm)

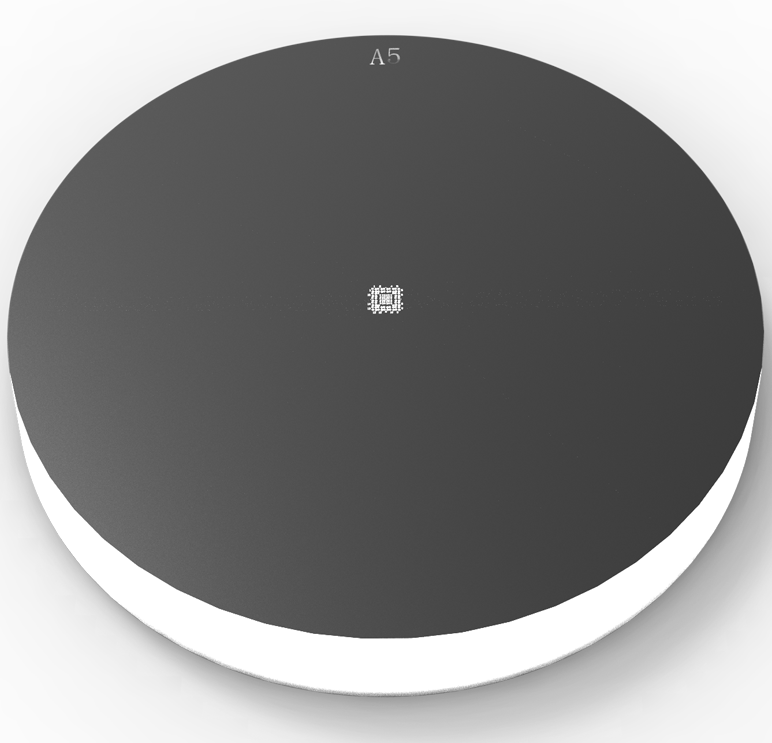

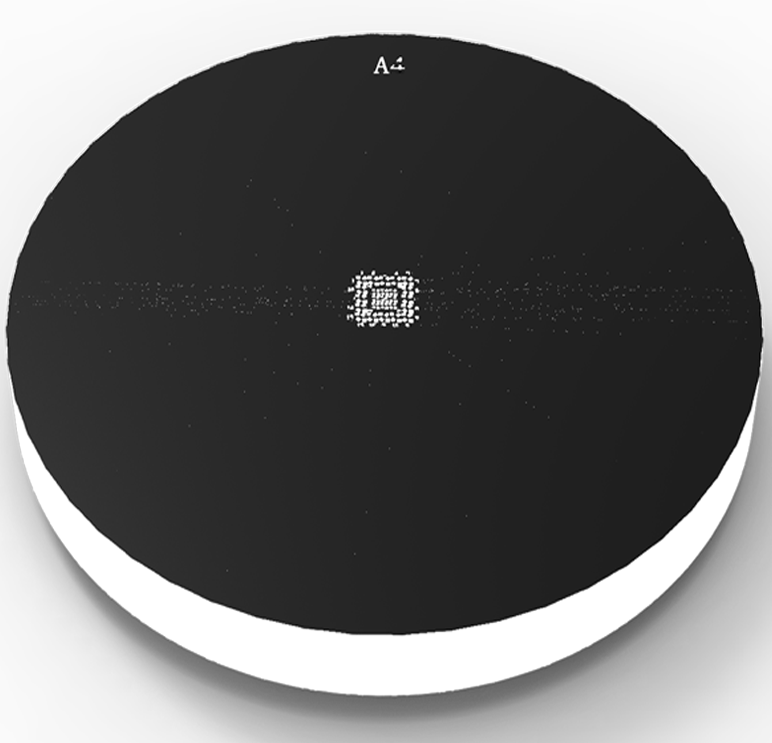

Visible Reticles: 13 piece(Crosshair Reticles*1,Resolution Reticles*6 :1#2#/3#/4#/5#/USAF1951,Star Point Reticles*5: 0.1/.01/0.2/0.02/0.05,Porro Board*1)

DC voltage stabilizing power supply: 1 piece (Output voltage:0-30V,Output current:0-5A)

Light Source Assembly: 1 set (12V20W halogen light source)

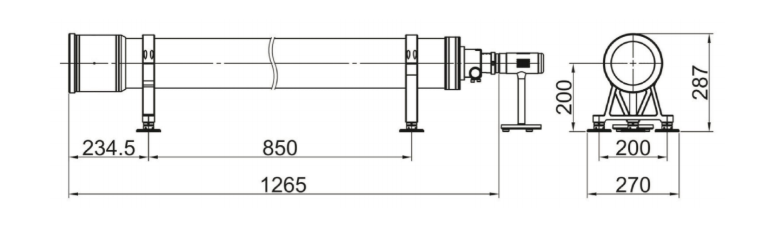

External dimensions:(Unit: mm)

About Us

YuLing Technology, headquartered in Chongqing, China, specializes in high-precision optical and photoelectric measuring instruments. With an R&D base in Xi’an, the company focuses on designing collimators, autocollimators, optical benches, and calibration devices for aerospace, defense, and metrology industries. YuLing integrates optical design, mechanical manufacturing, and electronic control, offering standard and customized instruments. Upholding a principle of quality and trust, YuLing provides reliable, high-accuracy optical products and technical support for clients worldwide.

Request detailed specifications or a tailored optical calibration solution from YuLing today!

FAQ – Frequently Asked Questions

How does the YuLing collimator achieve beam parallelism?

Each optical tube is tested with precision interferometers to maintain ≤10″ beam parallelism across its 1300 mm focal path.

What maintenance is required for the collimator lens?

Regular cleaning with certified optical solutions and periodic alignment checks are recommended to preserve accuracy.

Can the pinhole collimator module be replaced or customized?

Yes, YuLing offers interchangeable reticle and pinhole options for different optical testing setups.

What is the delivery time for customized models?

Standard production takes about four to six weeks depending on configuration and optical coating requirements.

Does YuLing provide calibration or technical support?

All products include one-year warranty coverage with post-delivery calibration and service guidance from YuLing engineers.